High-gap ink ejection technology

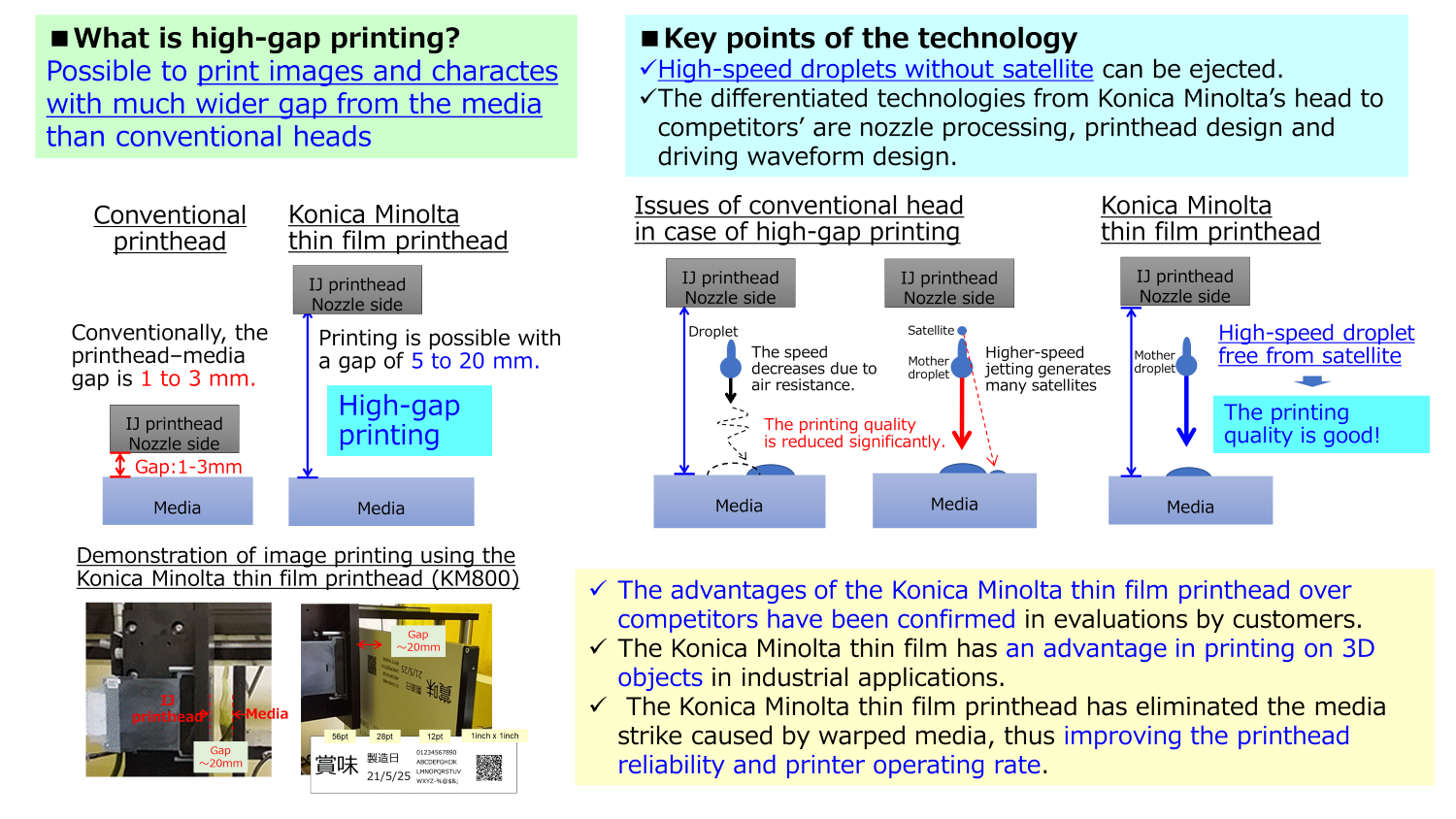

Achieving high-quality character printing even when the gap between the IJ printhead and the media is large

\Our expert team handles inquiries

on technical partnerships and joint research./

Achieving high-quality character printing on nonplanar base materials and three-dimensional objects by taking advantage of a large gap

Konica Minolta’s IJ printhead enables high-quality image printing with a large gap between the printhead and the media (media gap) compared to the conventional product. The large media gap can be applied to meet various needs, including printing characters on rough nonplanar media and three-dimensional objects, which are mainly required in industrial applications. Because a sufficient gap is secured, the printhead is less likely to strike warped media, thus improving the printhead reliability and printer operating rate.

Technology Overview

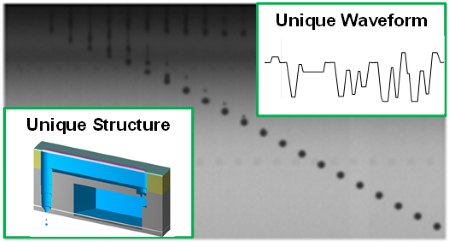

High-gap ink ejection technology has been achieved by combining thin film piezo technology, proprietary nozzle processing technology, ink flow path design, and driving waveform control (meniscus control) technology. These technologies achieve high-speed ink ejection while suppressing the generation of satellite droplets (small droplets separated from the ejected mother ink droplets). Ink droplets are placed on their target positions with high accuracy even if the gap from the media is large, producing high image printing quality.

Category to which this technology applies

(click to see a list of technologies in that category)

\Our expert team handles inquiries

on technical partnerships and joint research./