Hyperspectral imaging technology (HSI)

Realizing highly accurate determination and inspection by processing spectral information of visible light or higher frequencies

\Our expert team handles inquiries

on technical partnerships and joint research./

Contributing to safety, security, and environmental science through component inspection

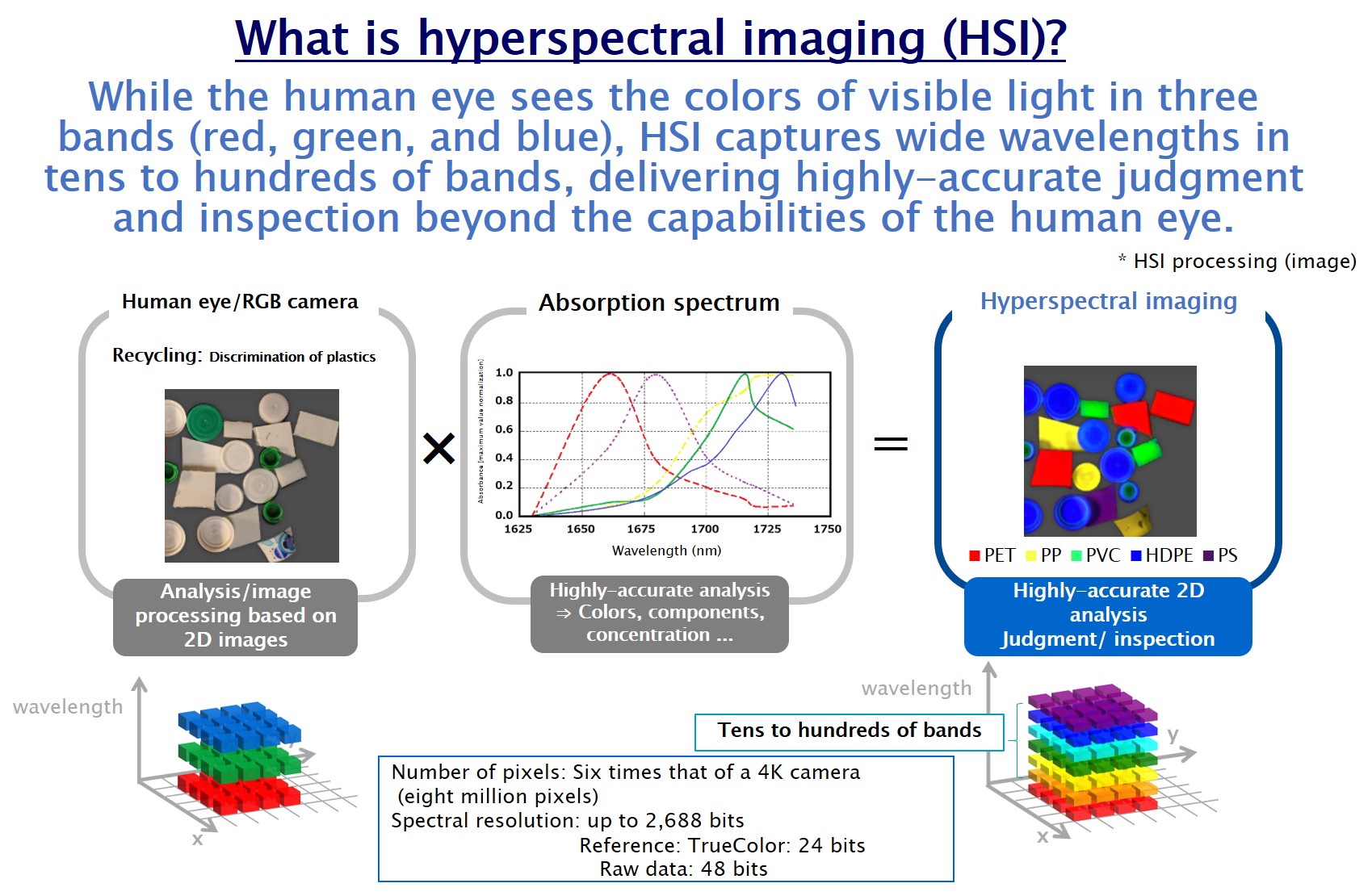

Previously, Konica Minolta’s sensing technology aimed mainly to measure colors based on visible light. We strive to visualize the invisible by expanding the light wavelength range from visible to infrared and using technology to analyze measured light. For example, white plastics that appear identical to both the human eye and an RGB camera may be of different types. This makes it difficult to sort different types of plastics, inspect food for foreign matter, and inspect pharmaceuticals for contamination during the manufacturing process. Hyperspectral imaging, a multi-wavelength spectrometry technology in the visible and infrared range, offers a nondestructive solution to determine target chemical substances. The technology will be used to automate sorting of plastics for recycling and inspection of food and pharmaceuticals for contamination with foreign matter in order to help solve environmental problems and effectively utilize resources.

Technology Overview

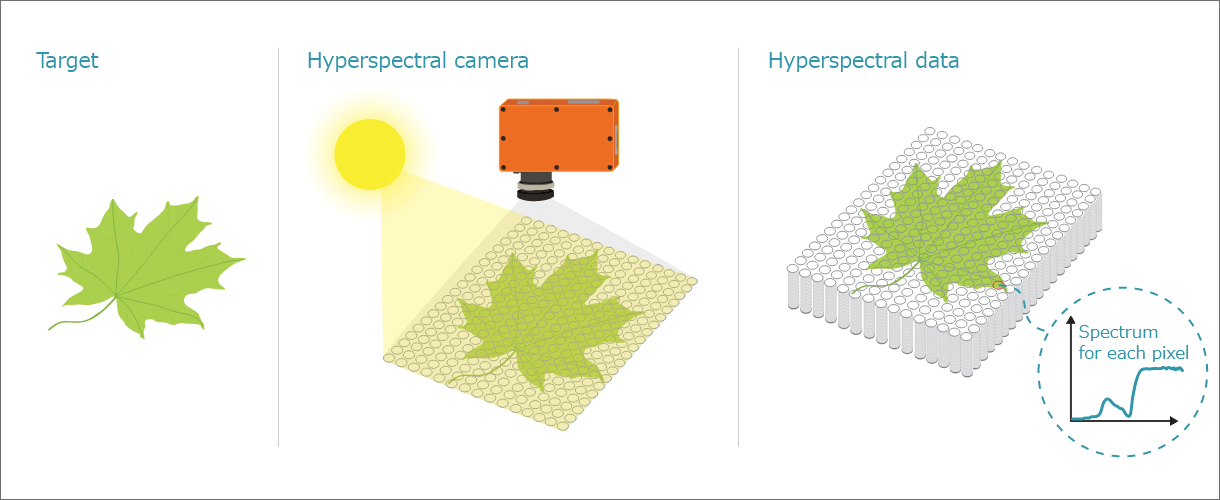

All materials and compounds absorb, radiate, and reflect light differently through interaction with light. Hyperspectral imaging can obtain the spectral signature, which represents optical spectrum patterns of absorption and reflection, which are peculiar to respective substances. It is a nondestructive solution to identify various materials and determine their characteristics. The technology, which combines spectroscopy with a scanning mechanism, can quickly obtain three-dimensional information (two-dimensional position information plus one-dimensional spectral information, which is obtained at each position) of measurement targets (“hyperspectral data cube”). The three-dimensional information makes it possible to conduct analysis and identify materials at each position.

Sensitive image analysis capability, and determination of contamination and distribution of invisible substances

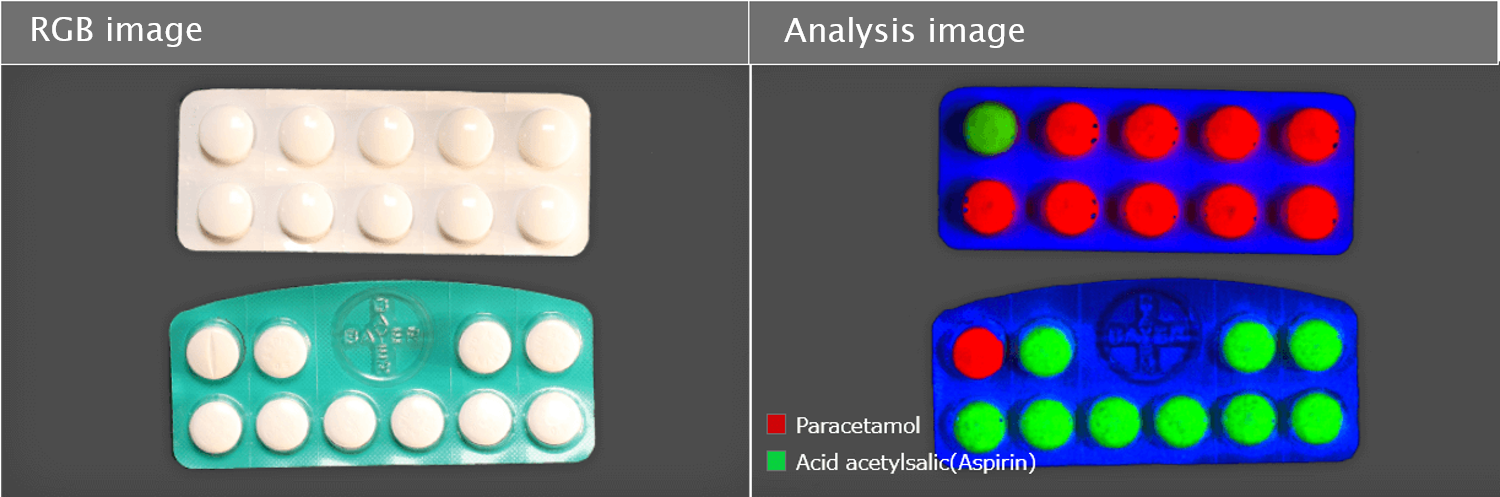

A hyperspectral camera can distinguish chemical substances, which appear similar to both the human eye and an RGB camera.

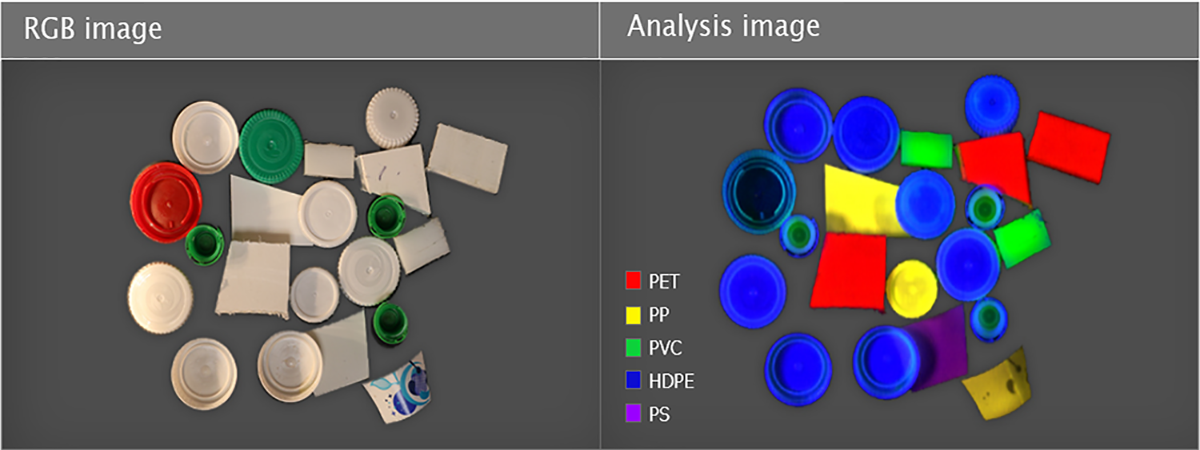

Figure 1 shows an example of plastic samples. The image on the left indicates the raw materials information perceived by the human eye and an RGB camera. While the human eye sees the visible light in three bands (red, green, and blue), hyperspectral imaging using a hyperspectral camera can capture wide wavelengths in several tens to several hundred bands, achieving high-accuracy determination and inspection beyond the capabilities of the human eye.

When recycling plastic products, it is important to properly sort them by material. Each plastic material has peculiar reflection characteristics. A hyperspectral camera can identify raw materials, such as PET, PP, PVC, HDPE, and PS. A hyperspectral camera that has light sensitivity for long wavelengths in the infrared range enables accurate sorting of black plastic materials, which used to be difficult.

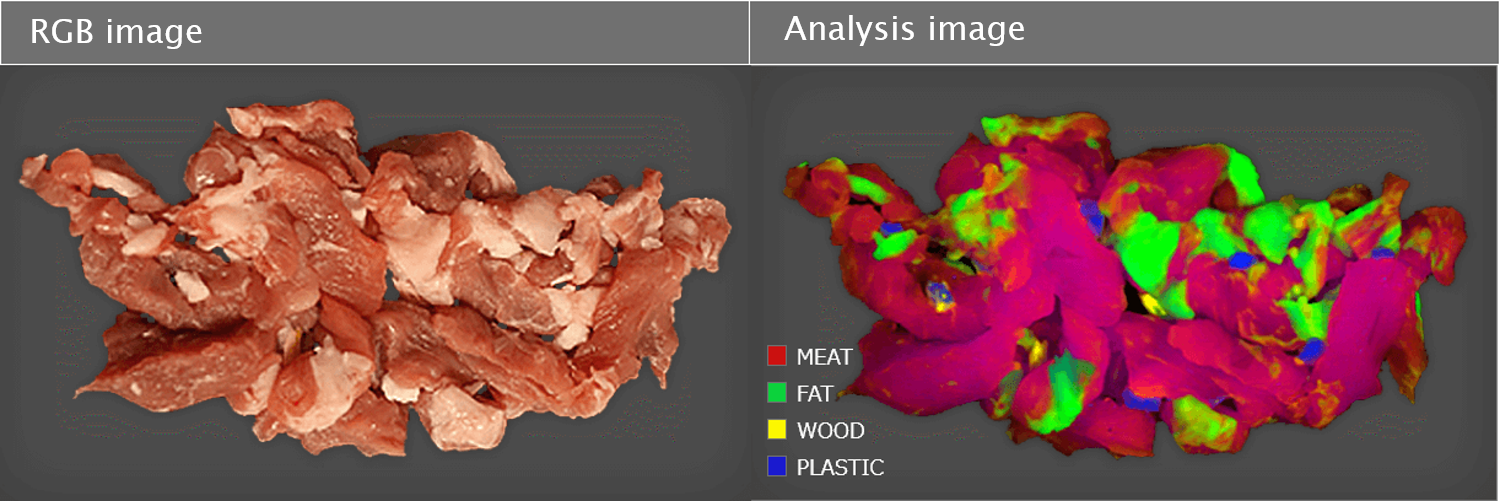

Foreign matter inspection and component inspection of meat and fish

HSI enables inspection to determine contamination with foreign matter, such as bones, cartilage, plastics, wood chips, and metal pieces, and identifies substances contained, such as chemicals, fat, protein, and moisture.

Quality inspection of pharmaceuticals

Pharmaceutical manufacturing requires quality inspections to check for contamination and the distribution of active ingredients. By installing a hyperspectral camera on a production line it is possible to analyze the ingredients and perform 100% inspection of their distribution.

Products and services that use this technology

Category to which this technology applies

(click to see a list of technologies in that category)

\Our expert team handles inquiries

on technical partnerships and joint research./