Multi-row thin type actuator technology

IJ printheads equipped with a unique harmonica structure achieving high-definition printing on various media

\Our expert team handles inquiries

on technical partnerships and joint research./

IJ printheads equipped with a harmonica structure actuator ideal for high definition and high productivity in industrial fields

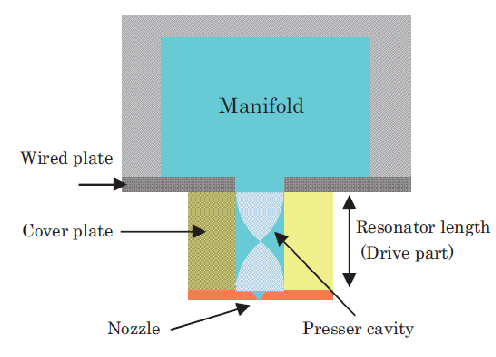

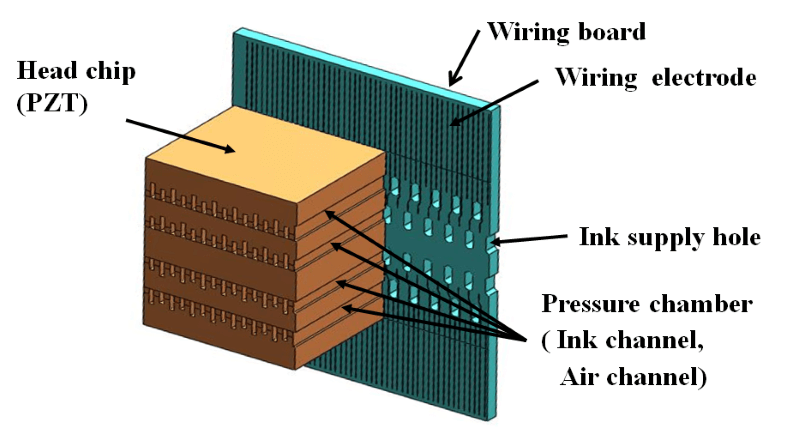

To meet the demand for high definition and high productivity in industrial fields, the “harmonica structure” actuator is characterized by low heat generation, high frequency drive, and multiple rows. Low heat generation not only reduces power consumption but also enables the continuous jetting of inks with constant viscosity at constant temperature, which ensures high-definition printing regardless of the copied state. Konica Minolta has also succeeded in introducing multiple rows to an actuator capable of driving at a high frequency, and can propose the optimum IJ printhead for each customer’s application. Furthermore, the thinnest IJ printheads in the industry have been realized with the multi-row design and can keep media gaps constant, so that our inkjet printers can perform high-quality printing also on three-dimensional objects, such as tubes and containers.

Technology Overview

Two technologies underlie the “harmonica structure” that enables high definition and high productivity in industrial fields: a technology for realizing a simple structure consisting only of a resonator, and a technology for producing printed circuit boards with high-density wiring in less space. The former reduces the capacitance of the actuator and thus contributes to efficiently using the pressure wave produced in the pressure chamber and to improving ink jetting sensitivity. The latter can produce multi-row yet compact chips by adopting high-density wiring and double-sided wiring.

Products and services that use this technology

Category to which this technology applies

(click to see a list of technologies in that category)

\Our expert team handles inquiries

on technical partnerships and joint research./