1

Overview

In biomanufacturing, monitoring of the culture, including the number, color, and shape of cells, and contamination by other organisms, is essential for stable manufacturing. The number of cells directly affects the yield as the production capability of target products. The color1) and shape2) of cells can reflect the metabolic status. Contamination leads to a decrease in yield and disposal of cultures. The risk is particularly high for microalgae that are cultured in open systems.3) Observation by microscope is a classic monitoring technique to quickly obtain cell information. However, microscopic examinations require significant manpower, and the results may vary depending on the technician. Therefore, we developed an AI solution to output the cell information based on microscopic images. The number and shape of cells of microalgae as well as contamination can be determined. The functionality to identify colors and determine cells of different varieties will be implemented. We will contribute to improving the productivity of biomanufacturing by both reducing the labor cost and obtaining detailed cell information.

2

Details

■Configuration

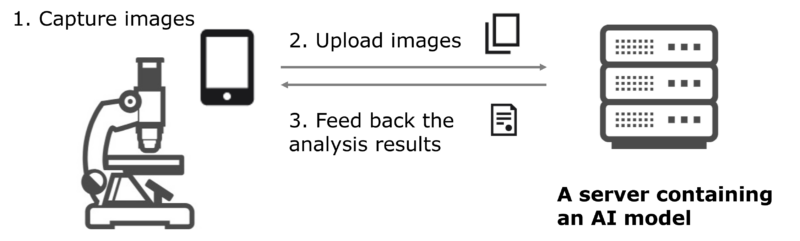

This technology consists of three main elements (a microscope, a camera (e.g., a smartphone), and an AI server) (Fig. 1). A simple microscope may be used. Images are obtained using the camera, including that of a smartphone, and are processed by AI on the server.

Fig. 1 Elements of this technology. Microscopic images are transferred from the smartphone, which is used to capture images, to a server containing an AI model. The analysis results are returned to the smartphone.

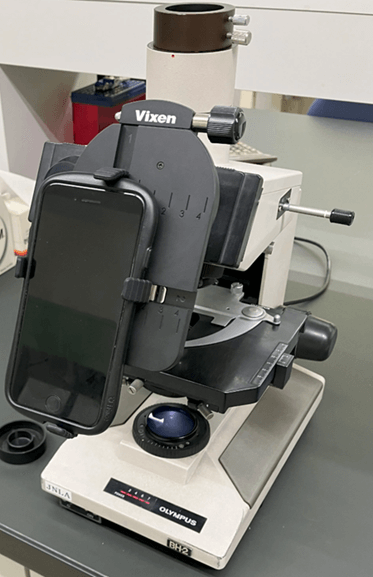

The workflow when using this technology is as follows. A smartphone is mounted on the microscope (Fig. 2). A culture sample, which contains cells of microorganisms, is set, and the focus is adjusted roughly on the sample. Images captured by the camera (Fig. 3) are transferred to the server, and the AI processing results are returned to the smartphone.

Fig. 2 A smartphone with its camera lens aligned to the objective lens of the microscope. A commercially available adaptor is used.

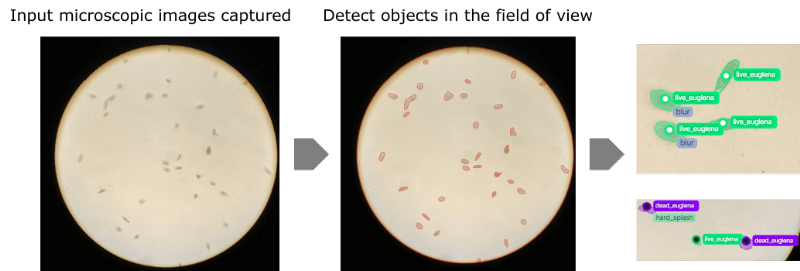

Fig. 3 A microscopic image captured by the smartphone. The image shows Euglena (Euglena gracilis) cells.

■Functions / Features / Applications

The main functions of this technology are to count the number of cells and determine the shape and contamination. We have started targeting microalgae. As shown in Fig. 4, the technology is used to detect objects, assess viability of cells, count the number, determine contamination, etc.

Fig. 4 Workflow to analyze captured microscopic images using AI. Objects contained in the image are detected and classified by object. In this example, the viability of Euglena (Euglena gracilis) is assessed based on the shape of cells.

This technology realizes functions that are fit for specific use cases by narrowing down species of organisms. Most commercially available microscopic image analysis solutions are not designed for specific use cases. By limiting the functions, it is possible to conduct high-accuracy analysis using a camera and a microscope with resolution available in the market without introducing expensive equipment.

Image processing is also possible when out of focus. When observing a culture solution, there are cells that cannot be focused on. This technology realizes determination even if cell images are blurry by using unfocused images for training, enabling inspection and ensuring sufficient quality without requiring accurate focusing.

This technology aims to simplify and refine the monitoring of microscopic cultures in biomanufacturing. With the globalization of manufacturing bases, quality control inspection needs to be simplified and improved. Inspections with inconsistent accuracy among quality control managers in different countries and with significant room for personal judgment (e.g., the use of a microscope) make it difficult to deliver uniform results. It is also difficult to introduce expensive products, such as microscopes that come with an image analysis function. This technology can lower the hurdle by reducing differences in accuracy among inspection personnel by using AI for determination and by using a smartphone and the cloud.

■Future outlook

We will target filamentous fungi, whose microscopic images contain a large amount of information. We also aim to accumulate data by using this technology to predict the growth curve, identify factors for culture conditions that are likely to result in contamination, and determine the metabolic status in a simple manner based on the color and shape of cells, etc.