1

Overview

In color quality management for industrial products, there are growing expectations for eliminating the work of producing color cards, assigning values, distributing them to suppliers, and managing them using color cards by shifting from management using actual references, such as conventional color cards, to digital color communication (hereafter referred to as “DCC”), which refers to management based on digital color data, thereby increasing the work efficiency and reducing costs. However, to realize DCC, it is necessary to minimize the performance differences between spectrophotometers (hereafter referred to as “Inter-Instrument Agreement”), standardize the measurement conditions of instruments across the supply chain, and compare the output color data based on the same standard. In addition, in recent years, there has been a growing number of industrial products whose quality is difficult to manage, such as dark-colored products, small products, and products with curved surfaces and shapes, due to sophisticated designs in various fields, such as automobiles, electrical equipment, smartphones, and construction materials. To solve these challenges faced by customers, we have developed the CM-17d vertical portable spectrophotometer, which is characterized by smaller differences between instruments, higher accuracy, and easier measurement compared to the conventional model (Fig. 1).

Fig. 1 CM-17d Spectrophotometer

2

Details

■Configuration

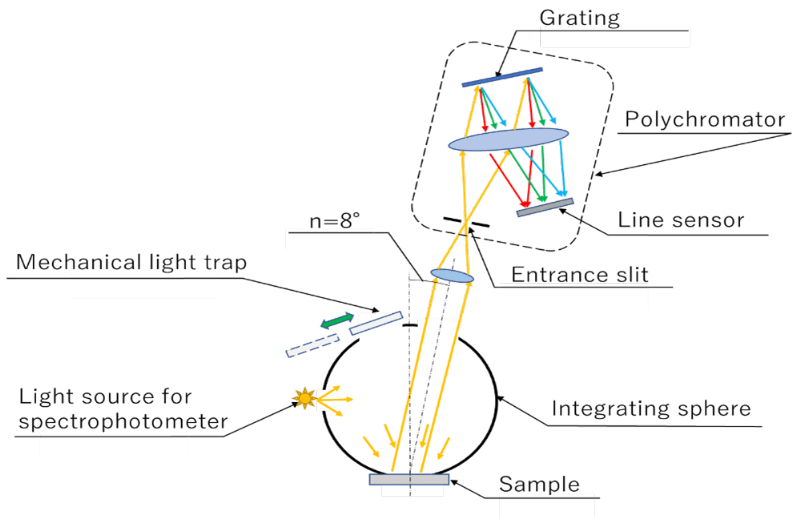

The CM-17d uses “diffused illumination/8° viewing angle (hereafter referred to as “d:8 geometry”)” that conforms to geometric condition c1) of JIS Z 8722 for the geometric condition of illumination and viewing in colorimetry. In the d:8 geometry, the light from the light source is diffusely reflected by the internal surface of the integrating sphere to expose the sample to light evenly from all directions. Of the light reflected from the sample, the light reflected in the 8° direction against the sample surface normal is diffracted by the diffraction grating. It is then viewed by a sensor to calculate the spectral reflectance based on the sensor output values and turn colors into numerical values. The integrating sphere is equipped with a mechanical light trap and is capable of automatically switching between measurement SCI (Specular Component Included), which contains the specular reflected light in the 8° direction, and the measurement SCE (Specular Component Excluded), which does not contain specular reflected light (Fig. 2).

Fig. 2 Internal configuration of CM-17d system

■Functions / Features / Applications

1) Electronic viewfinder that accurately identifies the measurement position

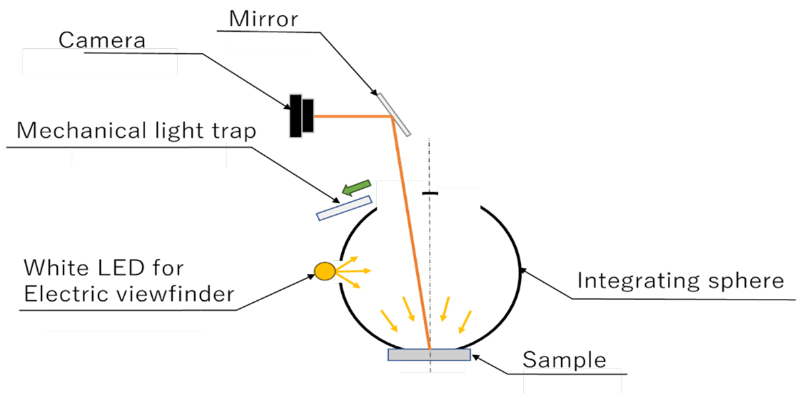

The electronic viewfinder function makes it easy to check the measurement area on an image, achieving accurate positioning (Fig. 3). To maintain colorimetry compatibility with the CM-700d, which is the conventional model,2) the camera is arranged in a position to look into the opening of the light trap, thereby ensuring the same geometric condition in colorimetry (Fig. 4).

Fig. 3 Electronic Viewfinder

Fig. 4 Electronic Viewfinder system of CM-17d

2) Highly accurate spectrophotometer that can be reliably used for DCC

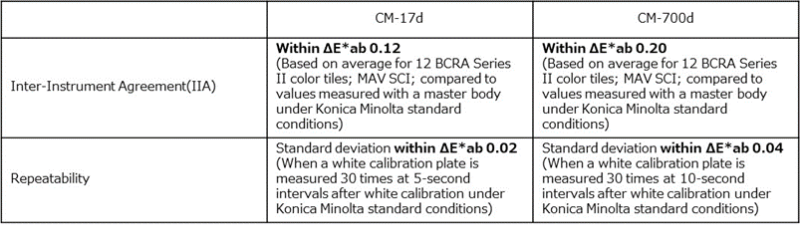

The differences between instruments have been reduced by about 40% compared to the conventional model, and the repeatability has been significantly improved. Thus, the specifications are suitable for DCC of industrial products with dark colors, including piano black (Table 1). In addition, the reliability has been significantly improved by the Wavelength Analysis & Adjustment (WAA) function, which is Konica Minolta’s proprietary technology to automatically detect changes in the wavelength direction of the spectrophotometer and make corrections.

Table 1 Performance comparison with conventional model CM-700d

3) Significant improvement in workability

Wireless connection with external equipment via wireless LAN and Bluetooth has improved workability. The cradle (Fig. 5), which has the zero-calibration box and can store white color calibration cap and performs charging, makes it easy to stow away the spectrophotometer after use.

Fig. 5 Cradle for charging

■Future outlook

We have introduced the basic technologies and new functions of the CM-17d, a high-accuracy and user-friendly spectrophotometer that can be used for DCC. Its applications are expected to further expand from the development of new materials, quality management of industrial products, and automation of inspection at production sites.