FLAIRS, a new evaluation solution that enables data-based analysis of the intuition and knack of skilled workers and sensory evaluations using AI

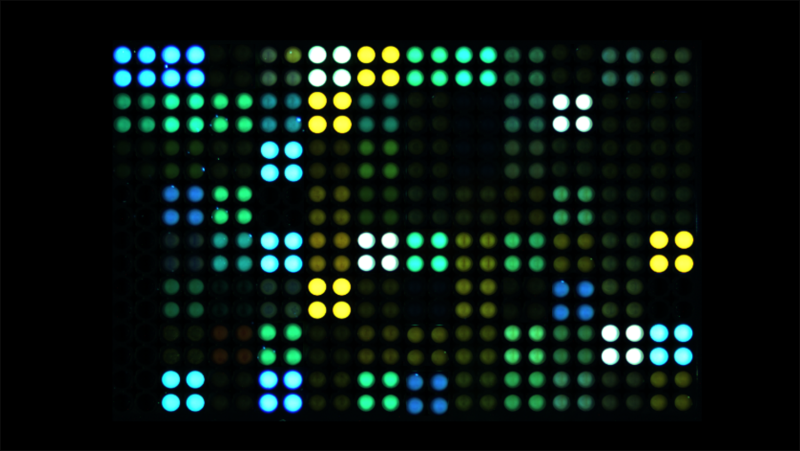

Capable of AI-based analysis of countless luminescent patterns of interactions to visualize differences that cannot be determined by numerical values

\Our expert team handles inquiries

on technical partnerships and joint research./

A solution capable of evaluating complicated targets by sensing and AI without simplification

This solution, which mainly targets liquids and other fluids, can comprehensively analyze the status and functions of an entire target without focusing on specific factors as in the case of conventional methods. Konica Minolta offers a unique novel evaluation technique through a combination of chemical sensing technology with AI.

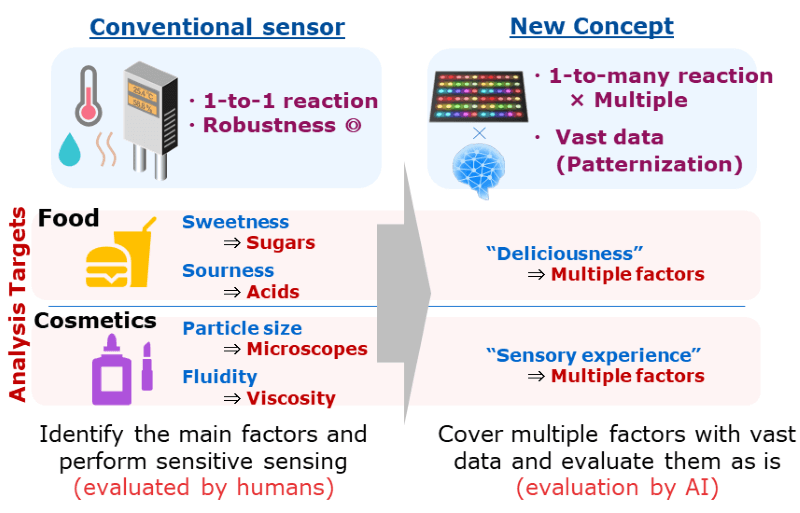

In general, conventional analyses and quality evaluations determined specific factors of influence based on numerical values. However, such a method required a considerable amount of time to identify factors of influence and sometimes overlooked the influence of unexpected factors. Unlike the conventional deductive investigation of cause, the new evaluation solution developed by Konica Minolta can comprehensively evaluate the overall status of a target based on an AI-based inductive approach. A measurement method which has sensitivity to multiple substances in addition to specific substances, analyzes the reaction pattern, and evaluates the entire target is referred to as a cross reaction method. This is a revolutionary method that innovates the conventional concept of analysis.

This solution is considered particularly effective in two main fields.

One is a field in which unexpected abnormalities are likely to occur. Because the entire status of a target is analyzed without dependence on specific evaluation items, the quality deterioration of pharmaceuticals, natural materials, and biomaterials can be detected before they are marketed. The solution can also be applied to authenticity verification. This method also makes it possible to cope with counterfeit products that are likely to be overlooked when conventional evaluation techniques are used.

The other is the usage as an alternative to craftsmanship and sensory evaluations. Introduction of this solution to processes that currently depend on human senses and experience is expected to help centralize evaluations and reduce differences.

We named this new solution “FLAIRS”* and are working on development toward practical application. FLAIRS is an abbreviation for FLuorescent Analysis with Inductive Recognition System. It is expected to be applied to many more fields in the future.

*:”FLAIRS” is a name for technology abbreviated from “FLuorescent Analysis with Inductive Recognition System” and is not a product or service name.

Technology Overview

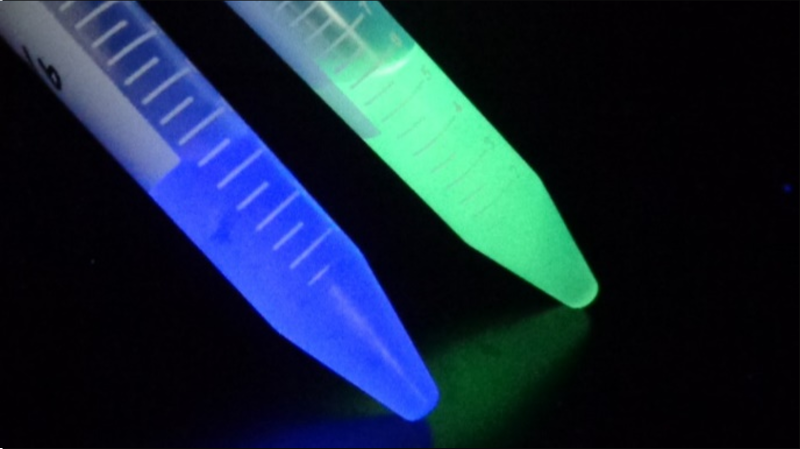

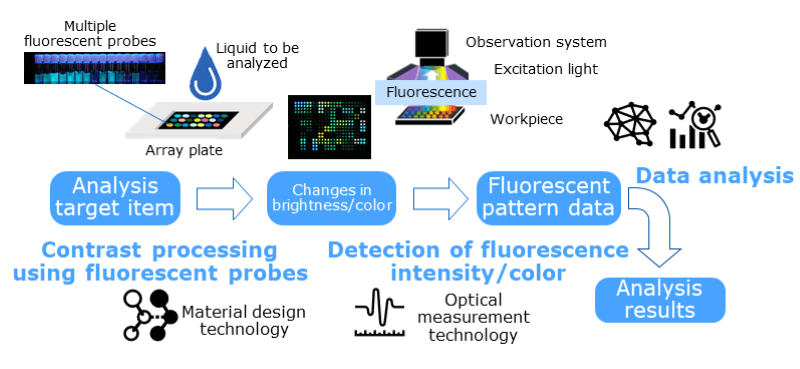

Two main factors are essential to realize this solution: a technology to develop versatile fluorescent probes that can capture any changes, and expertise to effectively process the obtained interaction data and enable AI to analyze it.

Fluorescent probes are created by combining optimal monomers from more than 300 types of monomers registered in Konica Minolta’s unique molecule libraries. This makes it possible to create countless fluorescent probes and thoroughly capture interactions with the target through reactions of any of the probes. The technology to generate countless fluorescent probes is underpinned by engineering capabilities to synthesize molecules, which Konica Minolta has accumulated through many years of product development. Konica Minolta also has technologies and expertise for designing and synthesizing new molecules to capture specific interactions depending on the measurement target.

In data analysis, the expertise and proposal formulation capabilities of our data scientists are our great strengths. Konica Minolta has acquired deep experience in data selection for data measurement and effective analysis in the course of applying material informatics (MI) and process informatics (PI) at its development and production sites and solving customers’ issues. This solution is a custom-made evaluation technique to perform optimal tuning depending on the measurement target. In the tuning process, we share issues in cooperation with customers and fully demonstrate the technology to reflect the solutions in AI analysis.

“

Example of application: Authenticity verification of counterfeit drugs

One example of using this system is for measuring genuine pharmaceuticals, which are available in overseas markets, and counterfeit drugs, which are developed as imitation products. The constituents of counterfeit drugs are unknown, and such drugs are often made to resemble genuine products, making it difficult to identify an appropriate measurement method using conventional measurement techniques. Furthermore, only some components and features of targets are analyzed in conventional techniques; counterfeit products can avoid being detected by inspections based only on specific evaluation items. This is a major issue in the pharmaceutical industry in particular where safety is the top priority.

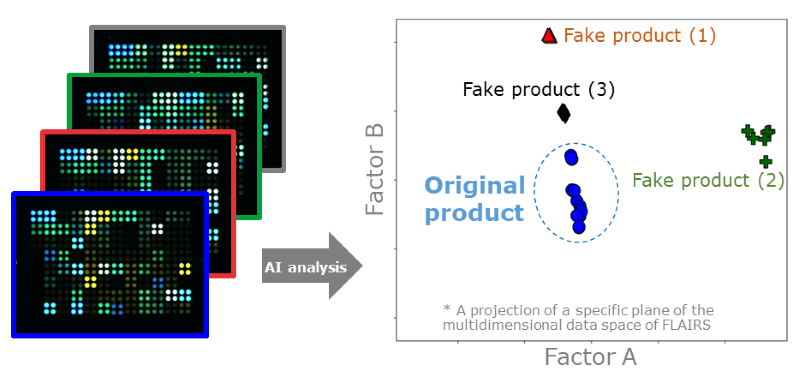

This system can capture features of targets without omission using various fluorescent probes and analyze genuine and counterfeit products in the multidimensional data space. In the latest example of implementation, measurement was conducted without pre-training of the system. We demonstrated that this versatile evaluation system can cope with unknown counterfeit products without being given any pre-training data on counterfeit drugs. As a result, it was verified that the system can reliably distinguish counterfeit drugs from genuine products without being given specific pre-training data.

Thus, this system realizes highly accurate authenticity verification beyond conventional techniques by using various fluorescent probes and AI analysis without depending on prior knowledge. This is just one of the successful applications of FLAIRS in a field where unexpected abnormalities are likely to occur.

“

Category to which this technology applies

(click to see a list of technologies in that category)

\Our expert team handles inquiries

on technical partnerships and joint research./