Free-form surface processing technology for optical elements

Achieving space-saving, high-resolution optical elements of the next generation

\Our expert team handles inquiries

on technical partnerships and joint research./

Space-saving, high-resolution next-generation optical elements realized by free-form surfaces

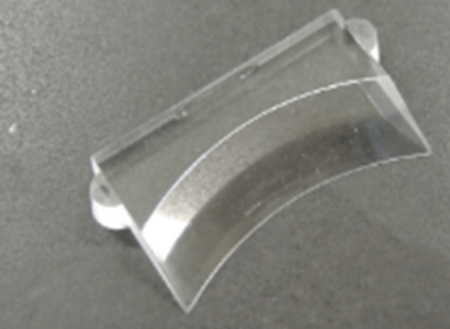

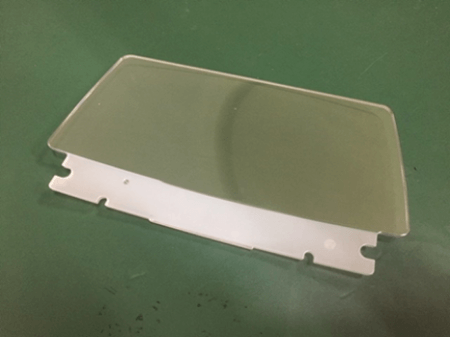

Optical elements having a free-form surface are used for in-vehicle head-up displays (HUDs) and for head mounted displays (HMDs) which are necessary for experiencing XR (cross reality) and are indispensable for implementing cutting-edge technologies in society.

Such devices must ensure high-resolution rendering in a limited space, such as inside the instrument panel in front of the driver of an automobile or the space above a person’s head. Thus, it is difficult to take the traditional approaches with a combination of multiple lenses, such as general spherical or aspherical optical lenses in order to have high resolution images. A single optical element that has a free-form created by this technology can be given multiple optical functions and thus save space while ensuring high resolution.

*XR is a generic term for cutting-edge technologies that combine the physical world with the virtual world, such as virtual reality (VR), augmented reality (AR) and mixed reality (MR).

Technology Overview

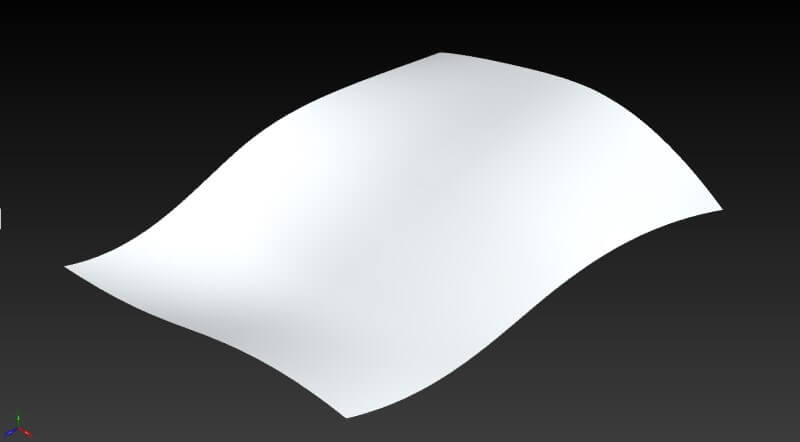

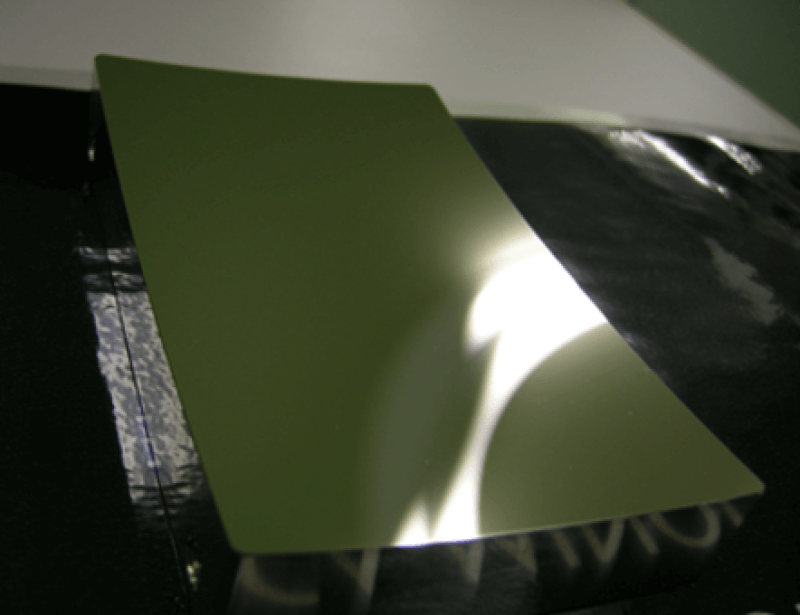

Free-form surfaces are a breakthrough technology that solves the trade-off between compactness and high accuracy. However, embodying design information that cannot be expressed by simple mathematical expressions requires sophisticated technological capabilities.

In particular, Konica Minolta excels at mold processing technology for creating free-form surface shapes. This advantage utilizes two capabilities.One is the ability to control a processing machine that has multiple movable axes by using software for creating processing programs (CAM) developed in-house. Another one is the ability to create a processing environment that can thoroughly eliminate errors. As a result, Konica Minolta is able to minimize shape errors of even elements with large surfaces. (Our technology can support surface sizes of up to Φ600 mm, while keeping surface roughness below 5 nm.)

Besides these manufacturing technologies, Konica Minolta excels at integrated manufacturing, including the preceding design process and the subsequent evaluation process. Our optical element manufacturing equipment, technologies, and know-how, which we have constantly honed through our long history, enable us to produce the optical elements with free-form surfaces required by customers.

Mirror having a large free-form surface shape

AR glass part

HUD combiner using a free-form surface

Products and services that use this technology

Category to which this technology applies

(click to see a list of technologies in that category)

\Our expert team handles inquiries

on technical partnerships and joint research./