Optical system design and evaluation technology enabling both outstanding optical performance and mass production

Minimizing defects in mass production by using simulation technology

\Our expert team handles inquiries

on technical partnerships and joint research./

Even very complicated optical systems can be smoothly mass-produced by accurately predicting mass production performance from the design stage.

Konica Minolta can provide an integrated package of high-level optical systems, from design to mass production, that meets customers’ requests. In particular, we are skilled at designing highly-accurate optical systems that can be mass-produced, using our know-how cultivated over many years.

We have manufactured and delivered Large optical system for cinema projectors, ultra-high-accuracy optical systems for semiconductor manufacturing equipments, and optical systems for AR/VR. We can also design highly complicated optical systems using free-form surfaces and DOE, and have designed a central fovea optical system (optical system having a high viewing angle and a high resolution around the center) for robot vision and in-vehicle sensing cameras for ADAS/AD.

Demand for this technology is being driven by stricter yet diversifying requirements for optical products and the trend toward shorter lead times in the entire manufacturing industry. Rework due to problems with prototype production and mass production may seriously affect commercialization plans. With Konica Minolta’s optical system design and evaluation technology, optical systems can be designed and smoothly shifted to mass production by minimizing in advance problems that are expected to arise during mass production.

Technology Overview

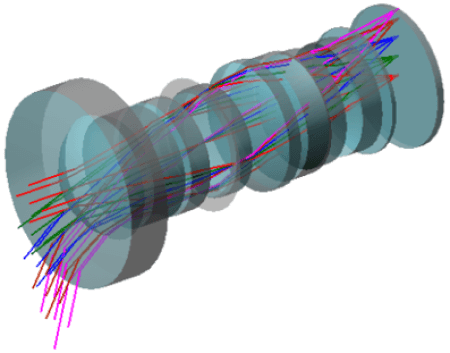

Two Konica Minolta-developed simulation technologies make it possible to develop an optical design that minimizes problems that may occur during mass production.

The first is a tool for predicting mass production performance. It evaluates the performance of simulated mass-produced lenses by artificially inducing manufacturing errors by the Monte Carlo method. In the case of imaging systems, the tool also performs up to rendering performance simulations. In this way, mass production performance can be estimated based on optical designs without actually manufacturing products. The key factors for simulations include the tolerances of lenses and mechanical parts, which are variables, and errors when mounting lenses, and they are appropriately adjusted by using Konica Minolta’s know-how.

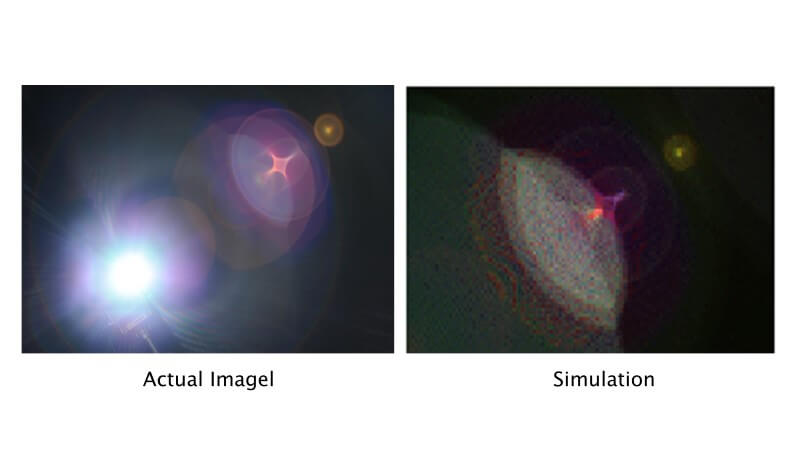

The second one is a tool for simulating ghosting. The impacts of unnecessary reflected light called ghosting can be accurately simulated by considering, for example, the characteristics of the anti-reflection coating applied to the lens surface.

In addition, using its design experience and know-how Konica Minolta can examine the balance between performance and mass producibility under various restrictions associated with advanced optical designs. In addition to these technologies and knowledge, the accurately keeping track of optical performance in prototype production and mass production enable us to embody appropriate feedback in designs and deliver high-quality products.

Actual image and simulation of unnecessary light

Category to which this technology applies

(click to see a list of technologies in that category)

\Our expert team handles inquiries

on technical partnerships and joint research./