Automatic inspection technology for automotive production lines

Automating the inline paint quality inspection of car bodies

\Our expert team handles inquiries

on technical partnerships and joint research./

Our unique vision system enables customers to resolve problems with automatic inspections.

The need for automation of automotive manufacturing lines is increasing due to shortages of manpower. Especially, most of visual cosmetic inspections of car body depend on human eyes wherein quality improvement/stabilization and manpower saving become significant issues. In addition to conventional color measurement of car exterior, Konica Minolta has acquired Eines Systems’ tunnel type defect inspection technology which enables the root causes analysis of defects in-line and auto-repair, with automated quality inspections and AI data analysis. Konica Minolta will also contribute to manufacturing lines for electric vehicles (EVs), which are expected to spread and evolve, with a wide variety of inspection know-how and technologies.

Technology Overview

Tunnel-type paint defect inspection system and flush&gap inspection system realize automated non-contact inspections in automotive production line.

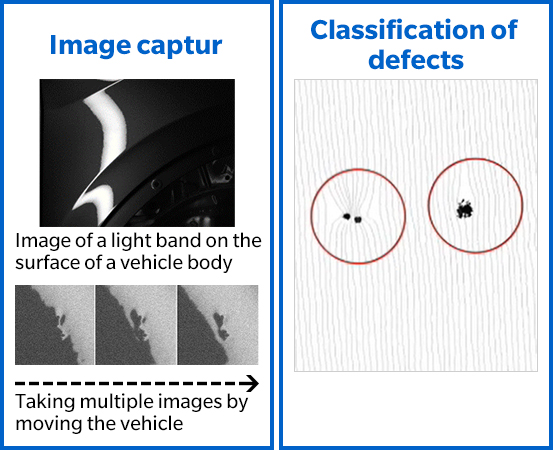

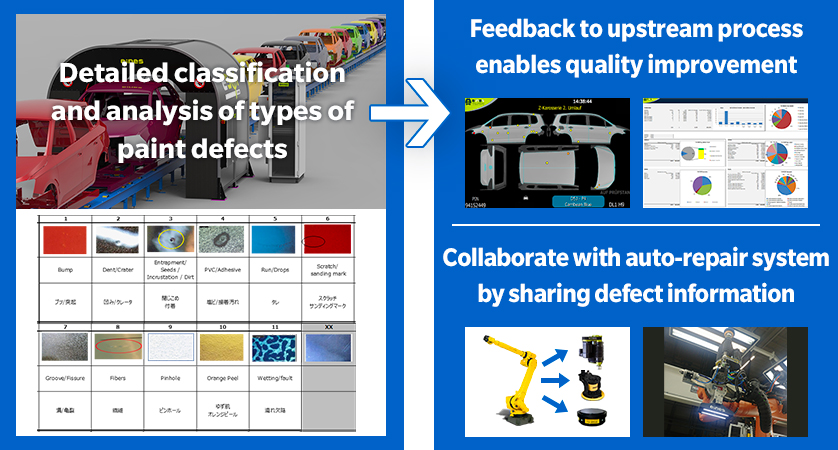

The paint defect inspection system can detect even defects as small as the diameter of mechanical pencil lead (Figure 1). It can also classify and analyze paint defects in detail with the aid of AI. This leads to feedback to upstream processes and collboration with automatic repair systems (Figure 2).

Unique tunnel type inspection system enables non-contact 100% inline inspection of flush & gap of automobile doors and fenders, which cause noise during driving and hinder the opening/closing of the doors (Figure 3) .

Figure 1

Figure 2

Figure 3

Products and services that use this technology

Category to which this technology applies

(click to see a list of technologies in that category)

\Our expert team handles inquiries

on technical partnerships and joint research./