Cerium oxide abrasive recycling technology

Realizing effective use and recycling of abrasives containing rare earth materials

\Our expert team handles inquiries

on technical partnerships and joint research./

Effective use and recycling of rare earth materials

Polishing powder containing cerium, which is a rare earth material, as cerium oxide abrasive grains is widely used for glass components for optical products, semiconductor products, glass for displays, and other applications because of its precise and high-speed polishing performance.

Although cerium oxide has high performance, it causes a heavy environmental burden throughout the process, from manufacture to use and disposal.

Accordingly, there has been strong demand to reuse it to ensure the sustainable use of precious rare earth materials.

Konica Minolta has established a recycling process for separating only the abrasive constituents from the slurry effluent used for polishing and restoring them to the pre-use state. With this technology, Konica Minolta is helping to create a sustainable society through the effective use of limited resources.

Technology Overview

To recycle used abrasive slurry, multiple types of chemicals and treatment processes need to be combined.

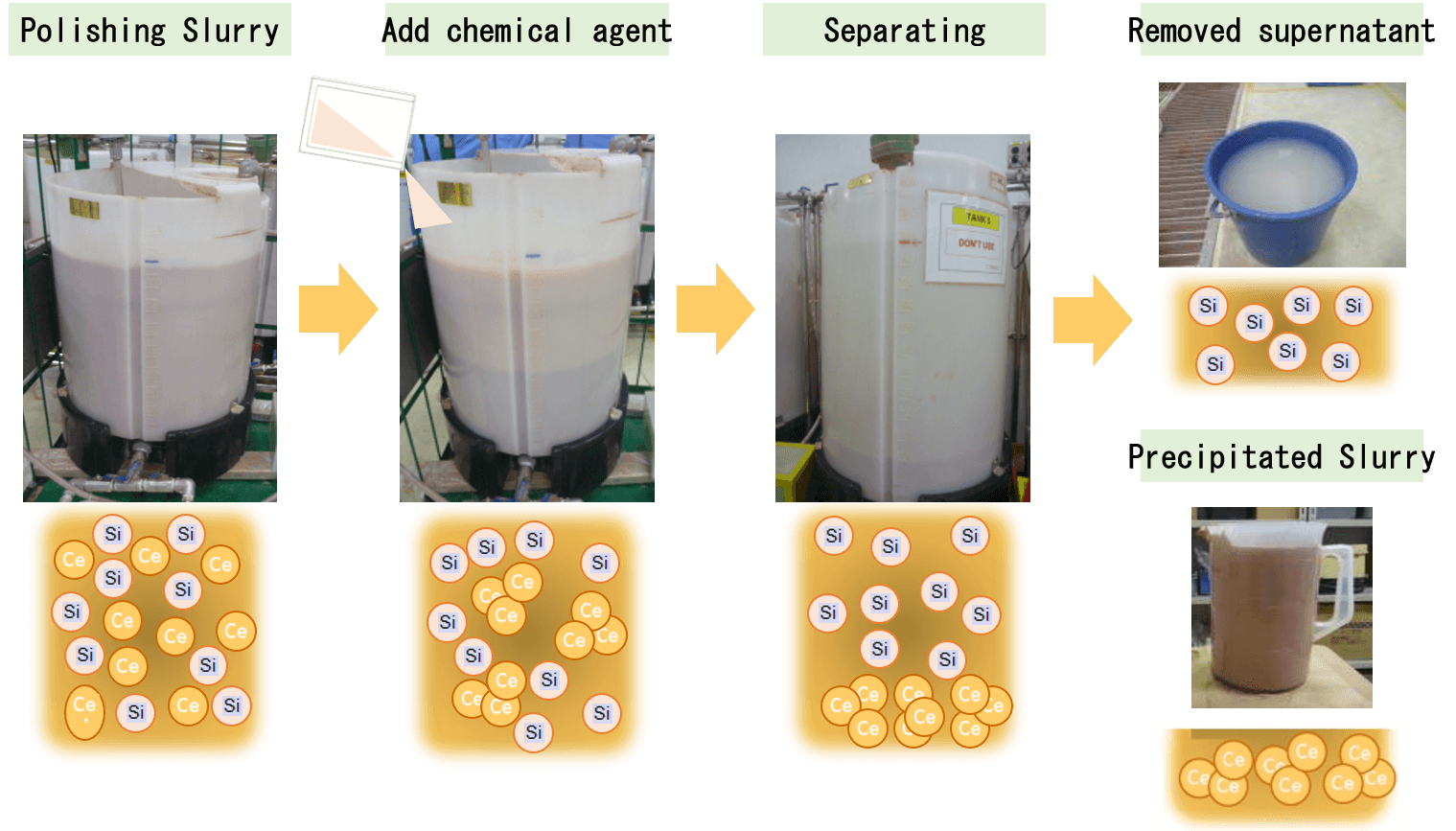

As the first step, a chemical that coagulates only abrasive grains is added to separate them from polished workpieces. By adding another chemical, the coagulated abrasive grains are redispersed and restored to an appropriate particle size. Through these processes, the slurry can be reused as cerium oxide slurry having the same performance as in the original state.

These technologies could not have been developed without deep knowledge of materials as well as Konica Minolta’s outstanding analysis technology.

Analyzing the adhering state of two constituents contained in abrasive slurry and scrutinizing the mechanism of polishing were important for selecting appropriate chemicals.

Furthermore, our analysis technology is useful for verifying that the abrasive grains do not get deformed or damaged even after polishing and that the composition of the slurry remains almost equivalent to that of new slurry.

This recycling technology is a good example of the excellent application of Konica Minolta’s core technologies.

Technology for analyzing the chemical states of surfaces for realizing the recycling of abrasive slurry

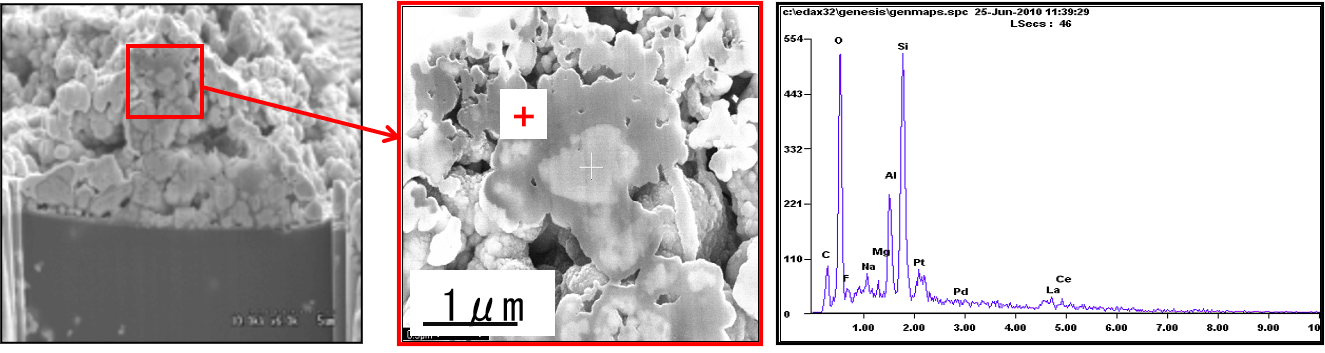

We analyzed the chemical state between ceria abrasive grains and glass constituents by analyzing the chemical state of the surface of cerium oxide particles before and after polishing.

When observing the form of commercially available cerium oxide abrasive grains after glass polishing, the presence of glass constituents was found around the abrasive grains.

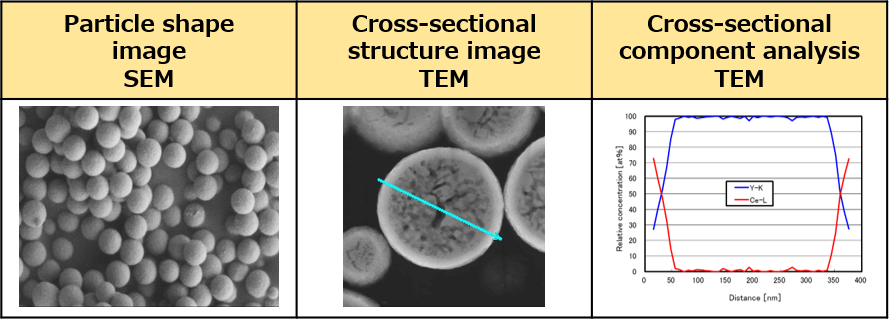

To analyze in detail the adhering state between the cerium oxide abrasive grains and the glass constituents, we polished an SiO2 film, which was formed by using an oxygen isotope, with newly developed spherical monodisperse cerium oxide abrasive grains, and analyzed the post-polishing state of the oxygen isotope using TOF-SIMS.

Migration of the oxygen isotope to the surface of the cerium oxide abrasive grains was not found. The analysis demonstrated that no chemical bonding existed between the cerium oxide abrasive grains and the glass constituents and they only adhered to (deposited on) one another.

TEM images (left, middle) of used polishing powder and element peak (right)

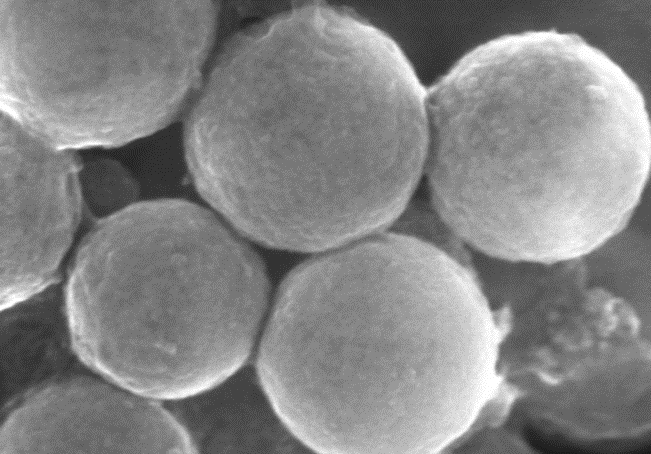

Spherical monodisperse cerium oxide particles

Advanced fine particle dispersion and coagulation control technology for realizing recycling of abrasive slurry

Based on the analysis of the particle, we achieved the recyling of abrasive slurry after polishing as polishing powder by adding to it a chemical, which selectively coagulates, sediments, and separates only cerium oxide grains, removing the supernatant liquid containing glass ingredients, and then redispersing the cerium oxide.

The key to success is the technology for freely coagulating and dispersing cerium oxide grains. In the first process, cerium oxide grains is coagulated in a relatively large particle size to reduce the loss of cerium oxide. In the following process, it is necessary to disperse the coagulated cerium oxide grains in an appropriate manner to ensure the optimum particle size for polishing.

Konica Minolta possesses a coagulation technology acquired through the production of polymerized toner, and a dispersion technology developed through the silver halide of photographic films. These core technologies enable highly controlled coagulation and dispersion of particles.

Newly developed cerium oxide polishing powder and its use for other applications

Konica Minolta has newly developed spherical monodisperse cerium oxide abrasive grains, which excel both in monodispersity and resource efficiency, as cerium oxide polishing powder. Analysis results prove that this cerium oxide polishing powder offers sufficient polishing performance for the flattening of semiconductor SiO2 films (silicon wafers) that require highly-accurate polishing. Compared to commercially available cerium oxide polishing powder products, the SiO2 film removal rate was improved to approximately 130%, and surface roughness was reduced by approximately 56%. The amount of polishing powder used for semiconductor manufacturing processes has been increasing year by year in response to the recent trend toward microsize and multilayer structures of semiconductors. Konica Minolta’s new cerium oxide manufacturing technology will contribute to the sustainable use of resources in combination with recycling technologies.

Application of analysis technology cultivated in the process of developing polishing powder recycling technology

As outlined above, Konica Minolta has long analyzed the chemical and physical states in which polishing powder particles and glass exist.

We are determined to introduce the analysis technology developed through this experience to new fields and thus help create a better society.

Chemically strengthened glass, whose manufacturing volume has been increasing for smartphones and other products, offers excellent durability but suffers from unstable quality.

Although 100% inspections have been desired for quality control, this is not easy at manufacturing sites which produce millions of sheets of glass a day.

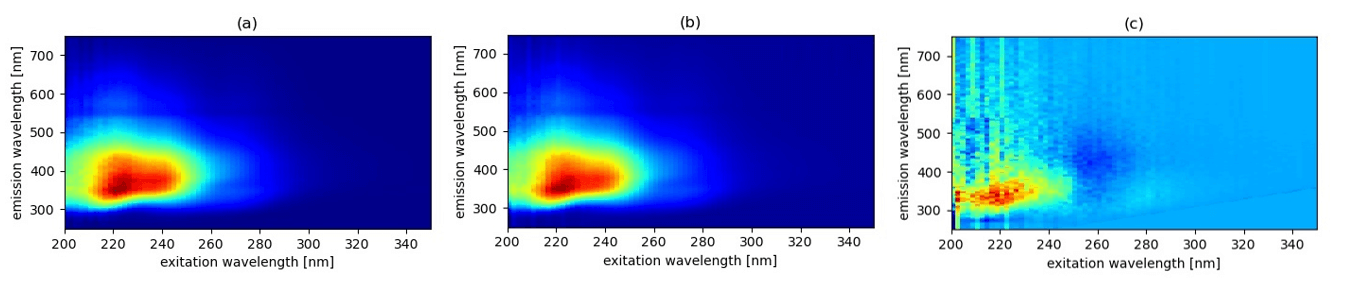

Thus, we focused on an optical inspection method capable of inspecting glass in a short time, and examined evaluation methods.

Optical emission spectrometry using X-rays enables us to grasp the state of existence of alkali ions in glass and evaluate quality.

By visualizing the quality of sheets of glass, which look transparent at a glance and are difficult to distinguish, we are helping to realize a society where people can easily use smartphones and other devices indispensable for daily life for many years to come.

The chemical strengthening-derived difference in the light emission characteristic is visualized by X-ray emission spectroscopy.

For more technical information

Category to which this technology applies

(click to see a list of technologies in that category)

\Our expert team handles inquiries

on technical partnerships and joint research./