Data analytics and sensing technology for remote maintenance

Constantly ensuring stable operation of customers’ MFPs through remote diagnosis

\Our expert team handles inquiries

on technical partnerships and joint research./

Copying and printing workflows are kept running without problems for many years by remote maintenance, regardless of the usage and environment

As a manufacturer of MFPs, Konica Minolta has been supporting the business of its customers and making steady progress with them for more than half a century. We ensure superb finished quality of printing, and offer remote diagnosis, maintenance and operation of MFPs since keeping equipment running is customers’ top priority. This commitment also avoids excessive replacement of parts and helps preserve the planet’s limited resources. Konica Minolta uses data analytics to create new workstyles in offices and future business scenes.

Technology Overview

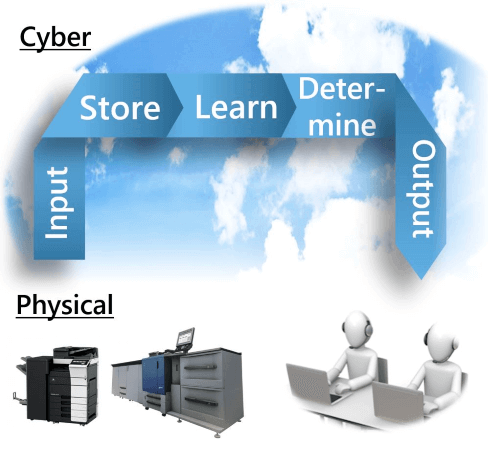

Typical situations in which customers cannot use their MFPs include stoppage for maintenance, paper jams, and running out of toner. We grasp the timing of maintenance, detect signs of paper jams, and predict when toner will run out by incorporating sensors into MFPs and analyzing the information from them. Furthermore, we integrate and analyze data collected from MFPs used around the world to improve prediction accuracy. Various factors are monitored, ranging from electrical characteristics inside MFPs and the operation of mechanical mechanisms to the environments where they are used. This approach combines our proprietary knowledge about physics, machinery, and electricity with data analysis technology and helps our customers use MFPs without anxiety.

Technology for predicting the life of image-forming units

The core of image-forming in electrophotographic technology is the organic photoconductor (OPC), which forms images with toner on the surface of an organic layer which is just several dozen micrometers thick. The life of the OPC is determined by the depletion of the organic film. We detect the thickness of the layer in real time during printing, and periodically estimate the timing of maintenance. Furthermore, we perform statistical analysis of the sensing results collected from MFPs used around world to improve the accuracy of the estimation. This prediction technology is used to narrow down maintenance frequencies and components needing maintenance and thereby prevent stoppages for our customers.

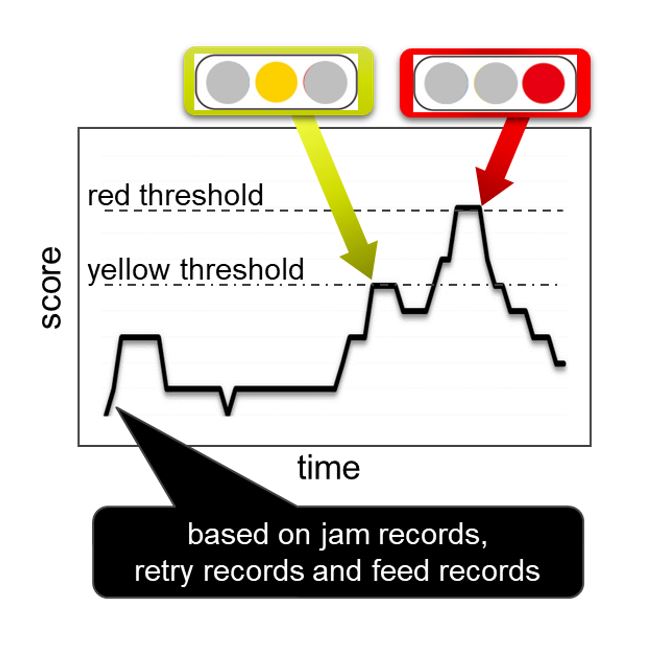

Paper feed status diagnosis technology and automatic adjustment of machine settings

Various types of paper are used in the market, and paper feed problems are one of the main causes of stoppages for customers. We have established a system for analyzing the signs and record of past paper jams and diagnosing and notifying the status of paper feed. We have also developed a mechanism that can detect the physical characteristics of paper and helps prevent paper feed problems by ensuring optimum paper settings.

Toner consumption prediction technology for automatic delivery of toner

Toner is a consumable that must be replenished, so each customer must keep a sufficient stock of toner to prevent MFPs from running out while reducing the space for storing toner. We are developing a technology for predicting the optimum timing of delivering toner to save time and labor for customers in managing and ordering toner, so they can concentrate on their business. This technology predicts the future consumption of toner based on the amount remaining inside MFPs and a record of past printing by each customer, and the optimum delivery timing based on the toner delivery lead time. We are also addressing the collective delivery of consumables and replacement parts in combination with a technology for predicting the life of image-forming units.

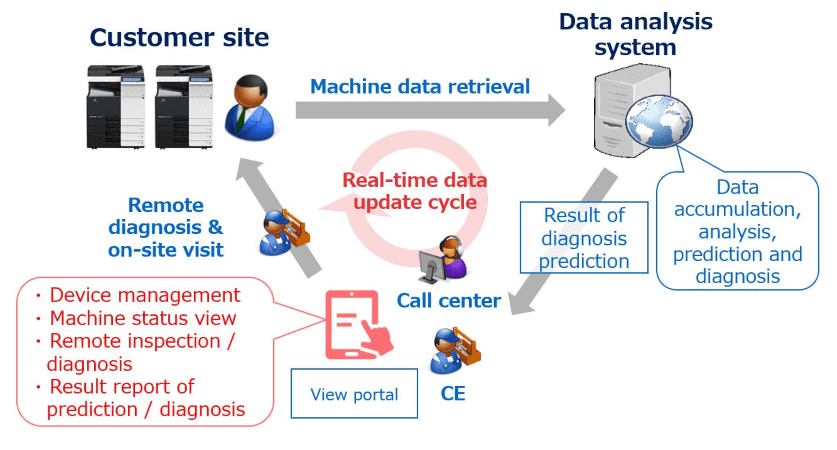

Information collection and analysis system for remote maintenance

We collect several hundred types of data from MFPs and analyze them every day. The data includes data on the status of image-forming units, paper feed status data, data on the status of use by each customer, usage environment data, and various other types of data. This data is used to virtually reproduce how customers use MFPs, and the impact of usage. The analysis results can be shared with the call center and customer engineers (CEs), so that even if a problem occurs, the service department can grasp the status of the MFPs in advance and conduct maintenance smoothly.

Category to which this technology applies

(click to see a list of technologies in that category)

\Our expert team handles inquiries

on technical partnerships and joint research./