Technology

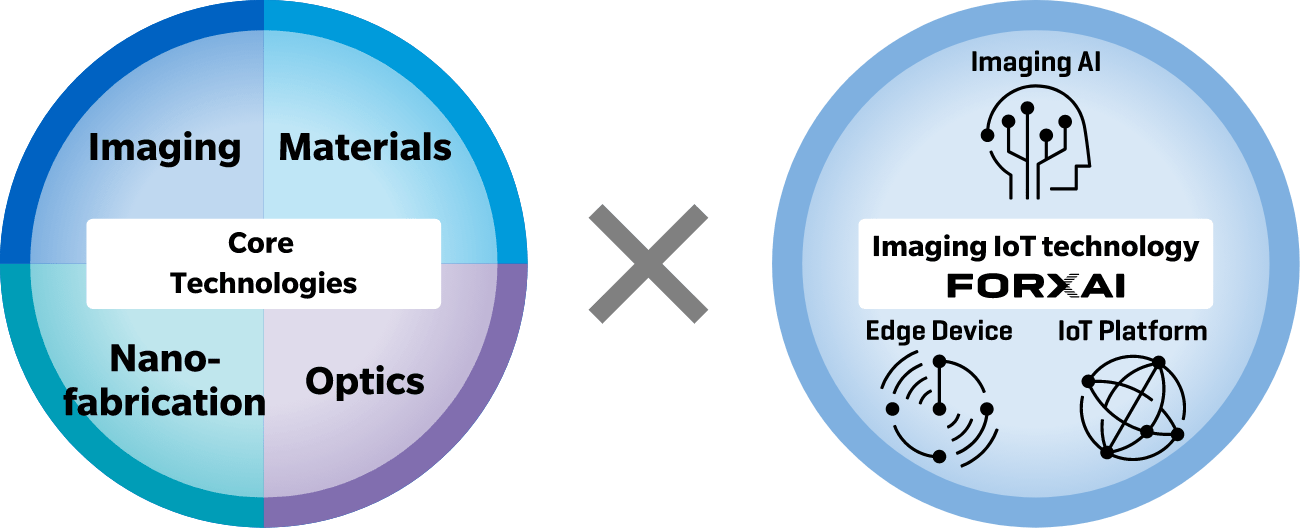

Overview of Konica Minolta Technologies

- Core technologies in four fields: materials, optics, nano-fabrication, and imaging

- Imaging IoT technology combining existing technologies with leading-edge AI and IoT technologies

Konica Minolta has created various products such as MFPs, X-ray systems and optical equipment which are based on its founding business of cameras and photographic films. While producing those products, the company has refined its four core technologies of materials, optics, nano-fabrication, and imaging. Combining the core technologies and seamlessly incorporating the latest ICT, Konica Minolta’s technological capabilities have culminated in its proprietary imaging IoT technology.

Core Technology

Imaging

Imaging technology consists of image input technology that generates image data from signals sent from various devices, image processing technology that converts and reconstructs image data for specific purposes, imaging process technology used to reproduce image data on a tangible medium, and image recognition technology for extracting and/or detecting intended objects with AI – capturing characteristic quantities from image data.

By combining these technologies, Konica Minolta has realized printing systems (MFPs, industrial presses, and inkjet printers) for office equipment, product inspection systems, and healthcare image systems (digital radiography and ultrasonic systems), as well as human behavior recognition for nursing care sites, occupational safety solutions, and bio-imaging, which are popular among a broad range of customers.

Materials

Material technology consist of technologies for forming fine particles, film-casting or coating technology and device technology by applying fundamental techniques of designing and synthesizing high-performance and/or composite materials for realizing required functions. Furthermore, with the aim of enabling efficient development and creating innovative materials, we utilize analysis and sensing techniques and actively combine leading-edge AI technology such as materials informatics (MI) and advanced simulation.

These technologies are used to produce polymerized toners, inkjet inks, and photosensitive materials for applications in office equipment, FPD scintillators and fluorescent nanoparticles for healthcare and biotechnology uses, and functional films (TAC and COP films) for displays and organic light-emitting diode (OLED) materials for industrial uses.

Optics

Optics technology consists of design, development, and production techniques for optical devices and systems that control or detect light (electromagnetic waves) emissions and techniques of using light to measure object colors, light source colors, and living body data. To measure a wide range of subjects, the wavelength range has been expanded from the visible range of the spectrum to the infrared region.

Applications include digital X-ray systems and living body data measurement (pulse oximeters and jaundice meters) in the area of healthcare, as well as monitoring cameras, ultrahigh sensitivity infrared sensor cameras for gas monitoring, X-ray nondestructive inspection, and hyperspectral imaging measurement for industrial uses.

Nano-fabrication

Nano-fabrication technology consists of high-precision molding technology for high precision and high-resolution optical components and MEMS process technology incorporating semiconductor fabrication processes. Combined with materials and optics technologies, nano-fabrication technology along with techniques used to evaluate formed nano-scale shapes and structures is a key to creating innovative devices.

Nano-fabrication is utilized for scanner lenses and high-resolution inkjet printheads for MFPs in office equipment applications, high sensitivity ultrasonic probes for healthcare uses, and, for industrial uses, diffraction gratings in optical measuring equipment and industrial inkjet printheads.

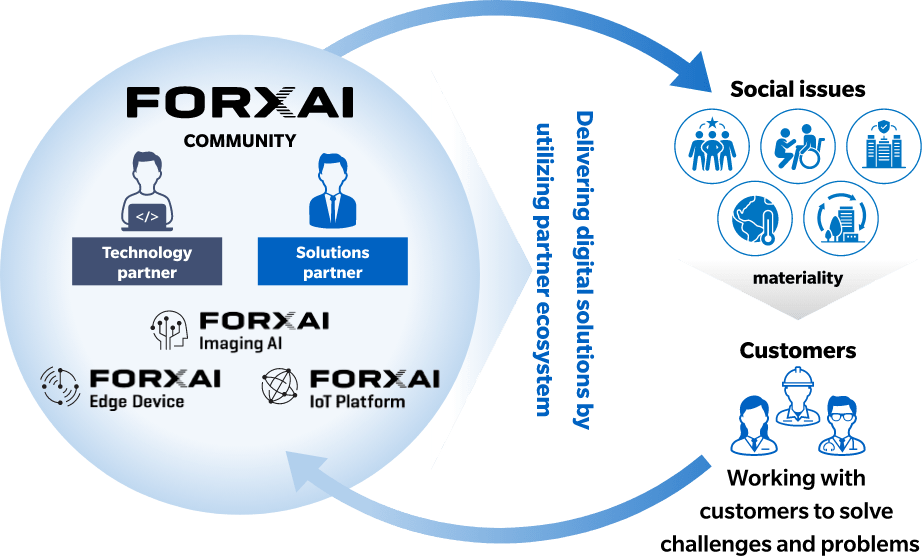

Imaging IoT technology

A three-pillar technology that combines Konica Minolta’s unique edge devices and/or other companies’ edge devices with cutting-edge imaging AI technology to provide customer value on IoT platform

Konica Minolta launched FORXAI as an imaging IoT platform (place for offering three technologies) that accelerates the social digital transformation (DX) involving our customers and business partners.

IoT Platform

A common IoT base for various fields, the IoT platform is the technologies for secure and easy integration of edge devices to the cloud to perform data management and AI processing.

Imaging AI

Technology for high-speed, high-accuracy, image-centric AI processing. Konica Minolta has established three areas of unrivaled competitiveness—human behavior, advanced medicine, and product testing—and have built an environment specialized in these areas and focused on developing unique AI algorithms. By combining the algorithm with Konica Minolta’s proprietary AI accelerator capable of running it quickly and with high precision, the imaging AI technology is world-class.

Edge Device

A group of devices that perform input/output and data processing to visualize and create value from field data.As its core technology, Konica Minolta has worked on image processing used for MFPs, cameras, and healthcare equipment. It is now developing its original device implementation technique for acquiring high-quality image data from manufacturing sites.