Material analysis technologies

Various types of analysis technologies underlying material development and production control

\Our expert team handles inquiries

on technical partnerships and joint research./

Technologies for communicating with “materials = substances”

Material analysis is a technology for “communicating” with materials composed of various “substances.” Through “communication” from the same standpoint as “substances” by means of spectra and images obtained from analysis as the common language, we can create revolutionary materials and achieve stable production of products and reliable quality control. “Communication” requires selecting appropriate pre-treatment and analysis devices for materials and interpreting analysis results based on advanced knowledge. Konica Minolta excels at this thanks to its 150 years of experience in handling various cutting-edge materials, including organic light-emitting diode (OLED), since its foundation.

Technology Overview

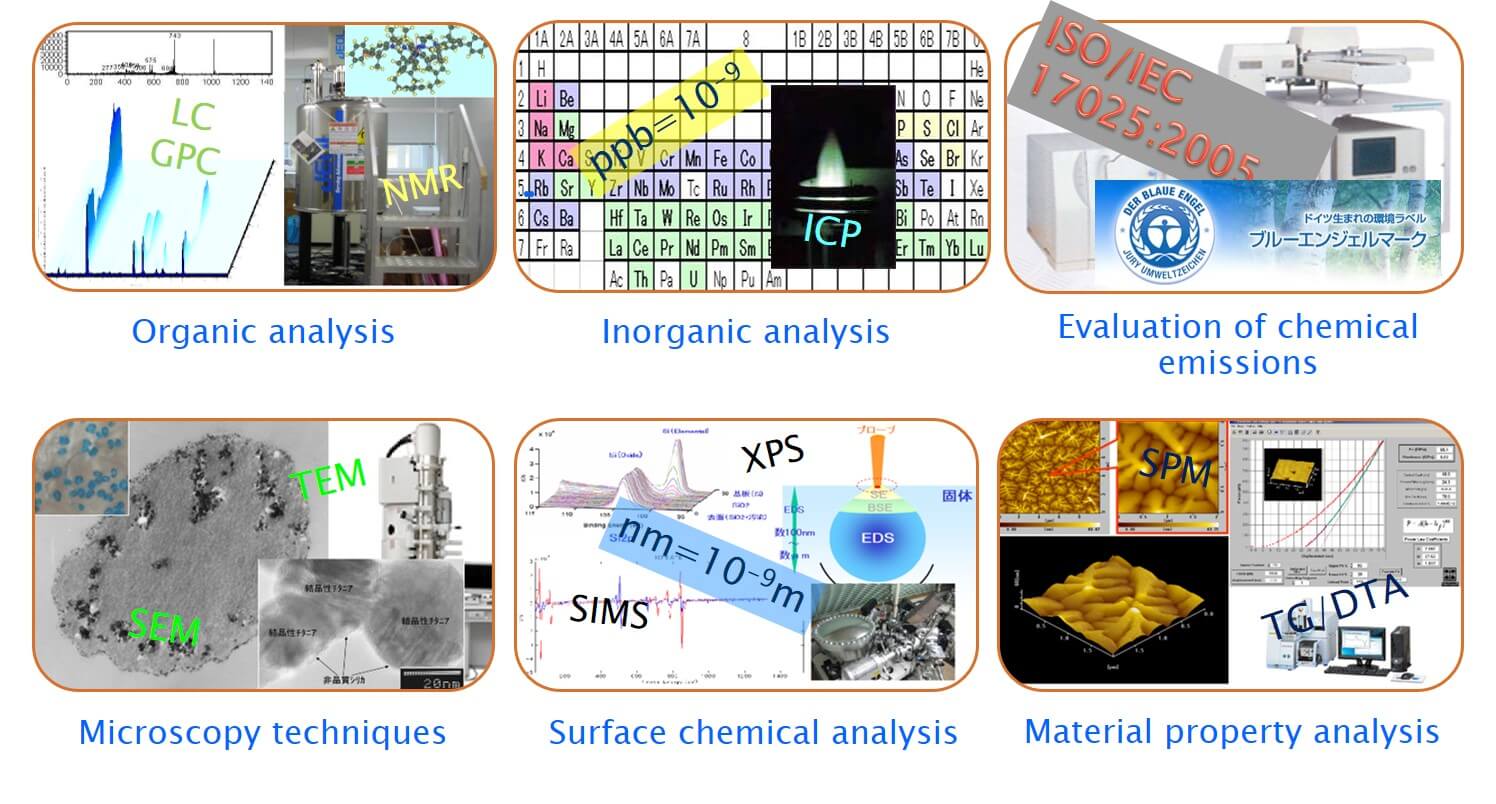

Konica Minolta classifies material analysis into the six fields shown above for the development of technologies. In each field, Konica Minolta has extensive knowledge and findings concerning the materials it has long handled. Konica Minolta excels at analyzing various types of films, composite resins, and thin membranes in particular; for example, for analysis using time-of-flight secondary ion mass spectrometry (TOF-SIMS), which is considered to be difficult to quantitatively evaluate, a high-accuracy measuring system realizing repeatability, constancy, and throughput has been established and applied to quality control; the system is highly regarded by external organizations. In addition, taking advantage of its knowledge and findings on establishing such measuring systems, Konica Minolta participates in activities for the international standardization of surface chemical analysis in collaboration with industry, academia, and the government and activities for diffusing analysis technologies.

Category to which this technology applies

(click to see a list of technologies in that category)

\Our expert team handles inquiries

on technical partnerships and joint research./