Printing paper automatic determination technology

Automatically setting the optimal printing conditions for media by using sensors and AI

\Our expert team handles inquiries

on technical partnerships and joint research./

Automating optimum printing settings for a wide variety of paper types

Since paper is an important factor that influences the texture and expressiveness of printing, a wide variety of paper types are used according to the application (books, catalogs, photobooks, etc.). Konica Minolta has been expanding both paper types to ensure high-quality printing, and the potential of digital printing by offering optimum printing conditions for each paper type. The setting of paper type and the selection of optimum printing conditions accordingly require both high skill and a knowledge of paper. By automating the setting of paper type and the selection of optimum printing conditions by means of our original technology, Konica Minolta has enabled anybody to easily produce attractive printed matter using various types of paper. Furthermore, this automation saves users time for printing preparations, reduces the time of low-volume production of various matter in which paper types are frequently changed, and improves the operation rate of presses.

Technology Overview

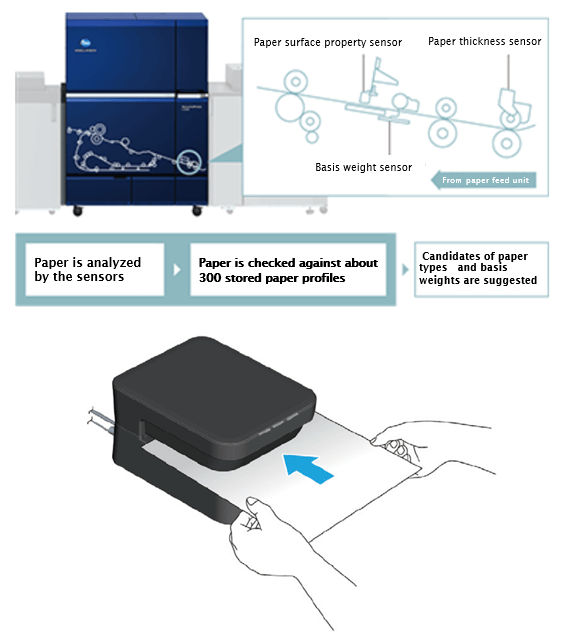

As for electrophotography systems, the finish of the image-forming process, such as transferring toner onto paper and fusing the transferred toner to the paper, is greatly affected by the characteristics of the paper, and so requires high-accuracy paper handling and paper conveyance. Thus, our system optimizes individual printing conditions by minutely sorting paper based on the basis weight (weight per unit area), which represents the characteristics of paper, and the paper type (coated or uncoated, surface roughness). In order to automate this setting of paper type, we have developed an algorithm that determines paper types from sensing data captured by sensors that detect the properties of paper (basis weight, surface property, thickness). This algorithm is used in professional printing products as an intelligent media center.

(Upper) In-line type (Lower) Off-line type

Paper property sensing technology

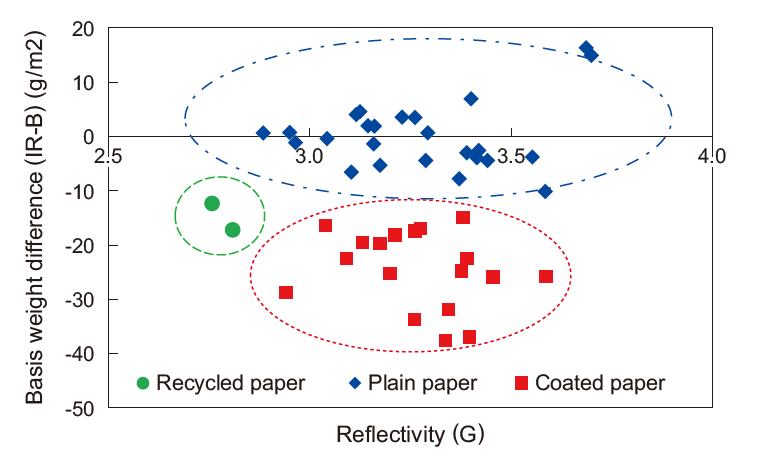

Classification of measured values of basis weights by paper type based on combinations of multiple wavelengths

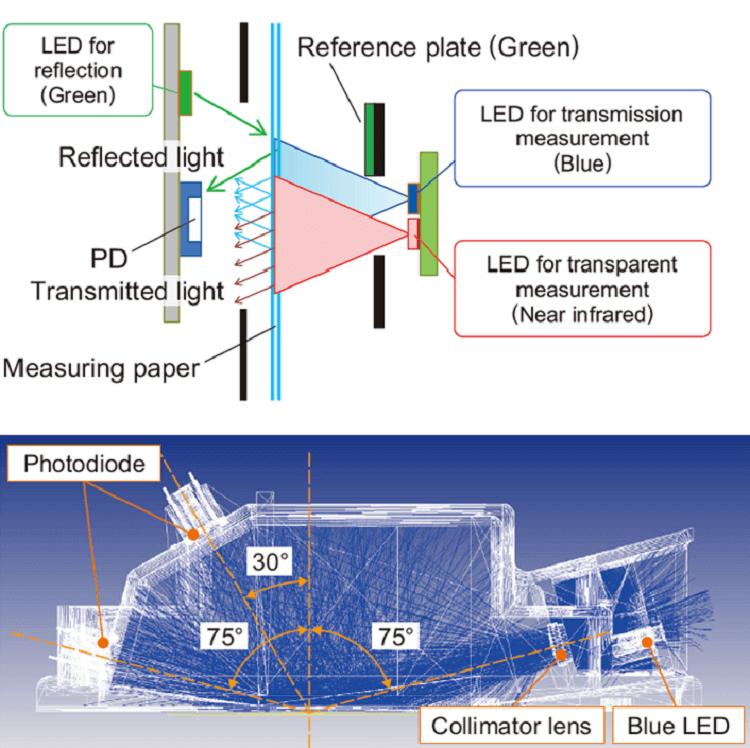

Konica Minolta has developed original sensors by analyzing data on the properties of more than 1,000 paper brands and selecting the properties of basis weight, surface property, and thicknesses, all of which are closely involved in determining a basis weight and a paper type. The basis weight is detected by a non-contact optical system using the light transmittance of paper. Since the amount of transmitted light varies depending on the chrominance attributable to the constituents of the paper, the impact of the constituents is eliminated by combining multiple light sources and wavelengths, so that various types of paper can be detected. The surface property is detected from the difference in the surface smoothness and gloss of paper using optical reflection characteristics. By combining two reflection characteristics, regular reflection and diffused reflection, it is possible to classify the properties, from coated or uncoated paper to the difference in the coating type. We have also developed a rotary encoder type sensor for measuring paper thickness. A difference of 5 μm can be detected by an algorithm that cancels roller eccentricity.

(Upper) Basis weight sensor (Lower) Paper surface property sensor

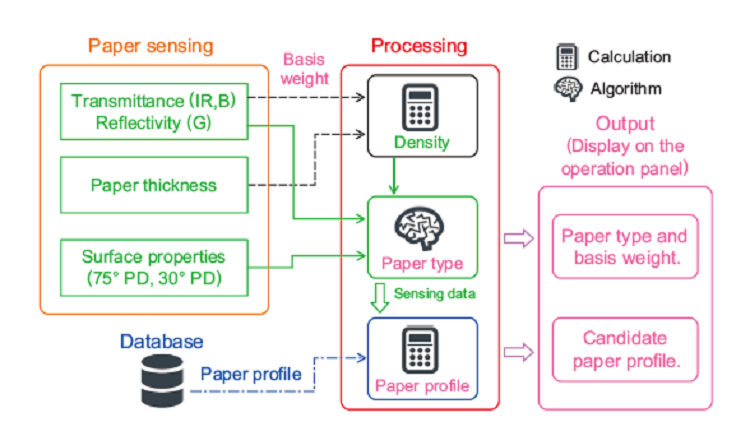

Paper type automatic determination technology

Block configuration of algorithm

Konica Minolta classifies paper based on combinations of basis weights and the following paper types:

● Plain paper (uncoated paper with a rough surface)

● Wood-free paper (uncoated paper with a fine surface)

● Matte paper (coated paper with a non-glossy surface)

● Gloss paper (coated paper with a glossy surface)

In order to determine paper types, we have developed an algorithm using machine learning. Paper types are determined based on values measured by the paper property sensor. For learning data, the paper property data accumulated by Konica Minolta is used, and learning is performed considering the error factors inherent in paper, such as the difference between the front and back faces, differences in grain direction, etc.

Category to which this technology applies

(click to see a list of technologies in that category)

\Our expert team handles inquiries

on technical partnerships and joint research./