Eco-friendly ink for apparel printing that preserves fabric functionality and texture

This eco-friendly ink reduces environmental impact by eliminating wastewater during printing, all while preserving the fabric’s natural functionality and feel.

\Our expert team handles inquiries

on technical partnerships and joint research./

Eco-friendly ink for apparel printing that preserves fabric functionality and texture

Printing on apparel using the pigment ink introduced in this technology offers two key advantages over traditional methods.The first advantage is that it allows users to enjoy printed designs while preserving the fabric’s original functionality and texture. For brand owners and fabric manufacturers, this means eliminating concerns about reduced fabric performance caused by printing or the need to impose design limitations, such as restricting print areas to maintain functionality.

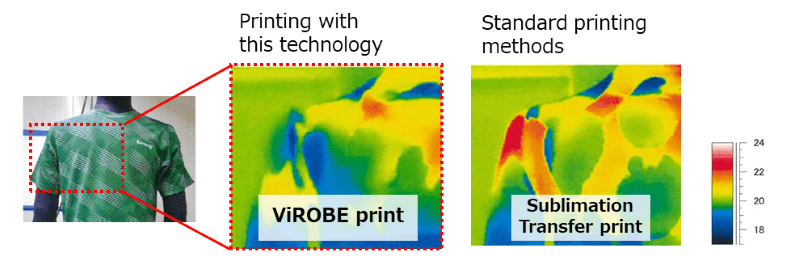

For example, when applied to sportswear, this ink enables users to wear their favorite designs without compromising performance or comfort. It helps maintain athletic functionality, such as regulating body temperature, and enhances comfort by preventing moisture buildup and ensuring a pleasant feel. Unlike conventional sublimation printing, which can degrade breathability and texture due to the heat and pressure applied during the process, this ink minimizes stress on the fabric, preserving its natural qualities.

The second advantage is that this printing technology is environmentally friendly, as it produces no wastewater. Unlike traditional printing methods, it eliminates the need for steaming and washing processes, which previously required 30 liters of wastewater per shirt. Additionally, it reduces CO2 emissions by 2 kilograms per shirt—a remarkable 89% reduction.Konica Minolta has developed this innovative pigment ink with these eco-friendly features and is presenting it under the brand name ‘ViROBE.’The name combines “vivid” and “robe,” symbolizing how the ink gently wraps fabrics in vibrant, beautiful colors.

Technology Overview

Leveraging over 20 years of experience in inkjet textile printing and integrating its core technologies, such as electrophotography and optical design, Konica Minolta has developed a groundbreaking pigment ink, ViROBE. This new ink not only retains the traditional advantages of pigment inks, such as compatibility with a wide range of fabrics, but also overcomes previous challenges. ViROBE achieves high color density and vibrancy, maintains fabric softness and breathability, and delivers exceptional durability—all features that were difficult to achieve with conventional pigment inks.The high color density and vibrancy are made possible through Konica Minolta’s expertise in optical design and its newly developed nano pigment dispersion stabilization technology, which controls light diffusion and refraction.

Traditionally, maintaining fabric softness and breathability while ensuring high durability has been a conflicting challenge for pigment printing. Konica Minolta has addressed this issue by taking advantage of the non-contact recording method offered by inkjet pigment inks, along with advanced material technologies developed in other fields.

For example, adhesive resin molecular structure and molecular weight design techniques, honed through toner synthesis, contribute to the flexibility of printed areas. Additionally, interface and coating control technologies, refined through the development of photographic film, are applied to precisely manage the surface and layers of printed areas.

A significant temperature drop inside the garment was observed when exposed to air, which was attributed to its high breathability.

[Measurement Conditions] In an environment of 20 ℃ and 65% relative humidity, a thermal mannequin was maintained at a constant temperature (set to 34 ℃). With a perspiration rate of 500 mL/(m2・h), air at a speed of 5 m/s was blown at a 45° angle in front for 30 min, starting at the same time as the operation. (Tested by UNITIKA GARMENT TECHNOLOGY Co., Ltd.)

Category to which this technology applies

(click to see a list of technologies in that category)

\Our expert team handles inquiries

on technical partnerships and joint research./