Non-Destructive Testing(NDT) for internal steels of bridges using magnetic and IoT

Contributing to the maintenance of social infrastructure

A nondestructive inspection solution to contribute the maintenance of aging social infrastructure

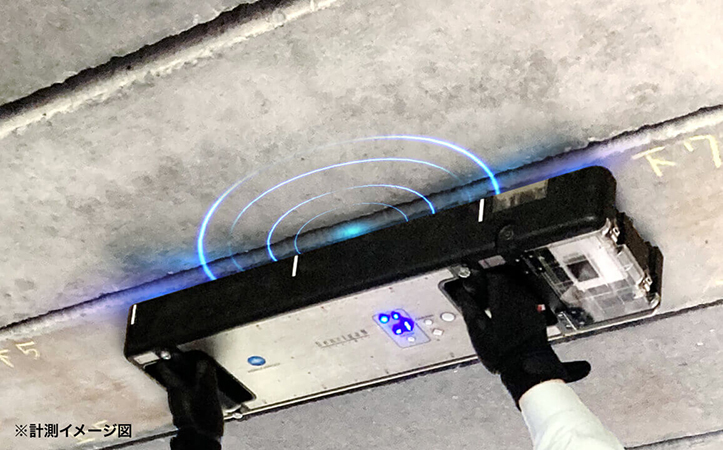

Aging infrastructure has become a global social problem. The service life of bridges is considered to be about 50 years. In Japan, 70% of 700,000 existing bridges will exceed their designed service life by 2035. Full-scale efforts to maintain infrastructure started due to the collapse of concrete ceiling panels in 2013. However, visual inpection is still used most widely for the appearance of infrastructure; internal inspection is very limited. To ensure appropriate maintenance of infrastructure, it is necessary to check ruptures of internal steel materials. SenrigaN, a nondestructive inspection technology developled by Konica Minolta, makes it possible to easily and efficiently locate ruptures inside steel materials so that bridges which require maintenance can be identified, thus contributing to more effective preventive maintenance of infrastructure.

Technology Overview

There are two measurement techniques: the magnetic flux leakage method and the magnetic stream method.

The magnetic flux leakage method involves magnetizing steel materials inside by placing a magnet outside and detecting the magnetic flux that leaks from magnetized steel materials. Because this method can determine changes in the magnetic field caused by ruptures, it is suitable for inspecting thin steel materials, such as prestressed concrete girders. Meanwhile, the magnetic stream method is designed to detect the magnetic forces that leak from steel materials inside while magnetic forces are applied. This method can determine sudden attenuation of magnetic fields caused by ruptures, so it is suitable for inspecting thick steel materials, such as post tensioned concrete girders.

We offer a nondestructive inspection solution (SenrigaN) based on both measurement techniques. SenrigaN system consists of a special magnet, a measurement device equipped with magnetic sensors, and SenrigaN cloud, which analyzes and visualizes the measurement results.