Non-destructive inspection technology using X-ray Talbot-Lau interferometry

Visualizing the distribution and orientation of fibers inside resins

Aiming to contribute to a sustainable society by using more resins in vehicles

Carbon fiber reinforced plastics (CFRPs) are lightweight plastics that can offer the same strength as metals, and so these innovative materials are expected to be used to reduce the weight of aircraft and vehicles. Practical applications have already started in some fields, such as aircraft. To apply CFRPs more extensively, it is necessary to further improve their performance and productivity. However, currently there is no technology for nondestructive inspection of the distribution and orientation of carbon fibers inside resins, which determine the performance, over a large area. Nondestructive inspection technology, which we are developing, will solve this problem, visualize the distribution and orientation of internal fibers, and clarify the correlation with the performance. We will thus improve the performance of CFRPs, increase the development and production efficiency, and help achieve a low-carbon society.

Technology Overview

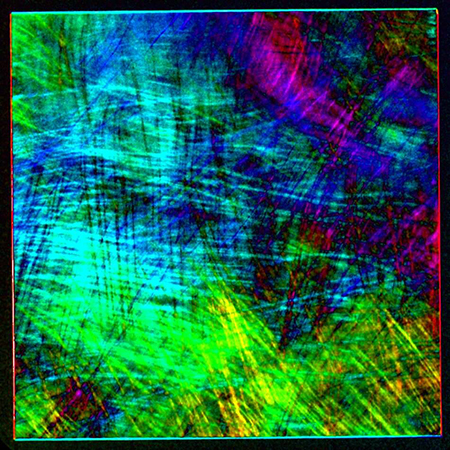

X-ray Talbot-Lau interferometry is a new X-ray inspection technology that can obtain three different X-ray images (absorption, scattering, refraction) in a single measurement. The scattering strength and orientation can also be identified by rotating a specimen and performing multiple measurements. Thus, the distribution and orientation of fibers and the presence of voids in CFRPs can be visualized from a relatively wide field of view. By comparing the results with those of mechanical tests, it is possible to identify the causes of destruction and develop better materials, structures, and manufacturing methods. We aim to make various contributions, including material design, manufacture, and quality assurance of CFRPs, by verifying the accuracy of resin flow simulation, predicting the rupture strength and position based on machine learning, and visualizing the progress of destruction based on in-situ measuring in tensile tests. We are studying the possibility of deploying the technology to other fiber-reinforced resins and other materials.