Chemical sensor in the era of AI — Acquisition of multidimensional data using fluorescent molecules

Any differences and changes detectable by countless fluorescent probes

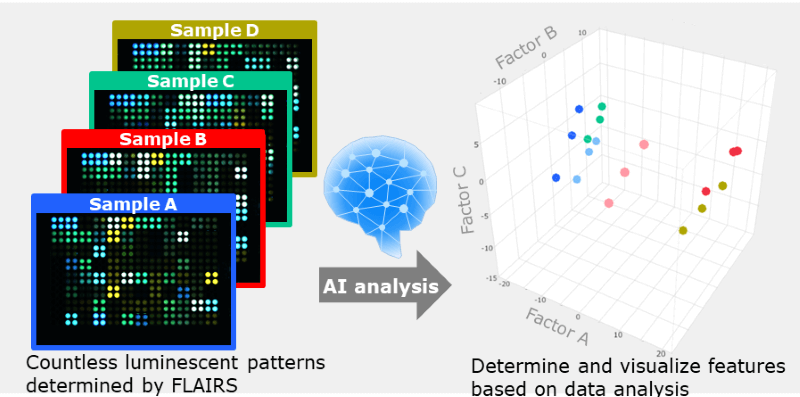

Development of a versatile data collection technique based on AI analysis

“The fluorescent molecule sensor developed by Konica Minolta collectively acquires a huge amount of data on interactions with measurement targets by using various molecules to detect subtle changes. Previously, analyzing large amounts of data imposed a heavy workload. Combination with AI analysis has enabled immediate conversion into useful information.

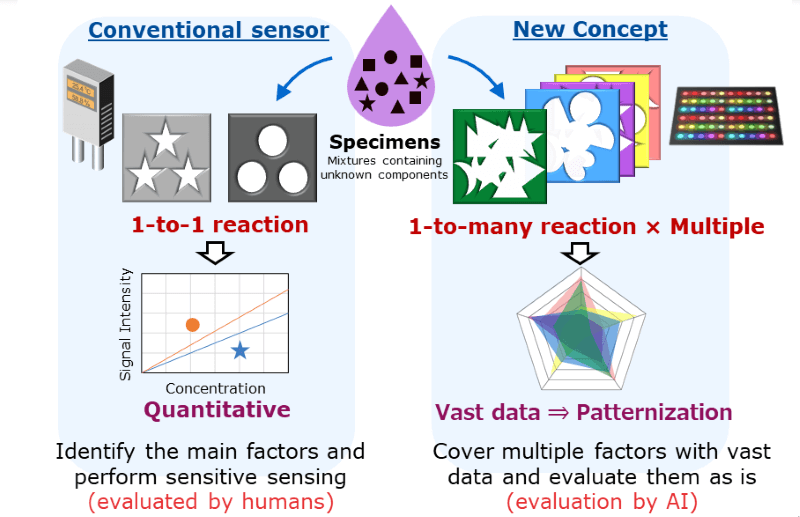

With conventional chemical sensors, researchers first needed to elucidate specific changes and factors of influence and then develop a sensor for determining such changes and factors based on 1-to-1 reactions. This limited the scope of application. In contrast, this sensor generates a huge amount of multidimensional data from various molecule libraries, enabling reliable determination of phenomena that are not easily understandable by humans. This helps eliminate the process of identifying factors of influence in advance, making this technique highly versatile.

This technology, which approached the innovative data collection technique based on AI analysis from the viewpoint of molecular design, was realized thanks to Konica Minolta’s material technology refined through many years of product development, including photographic films.”

Technology Overview

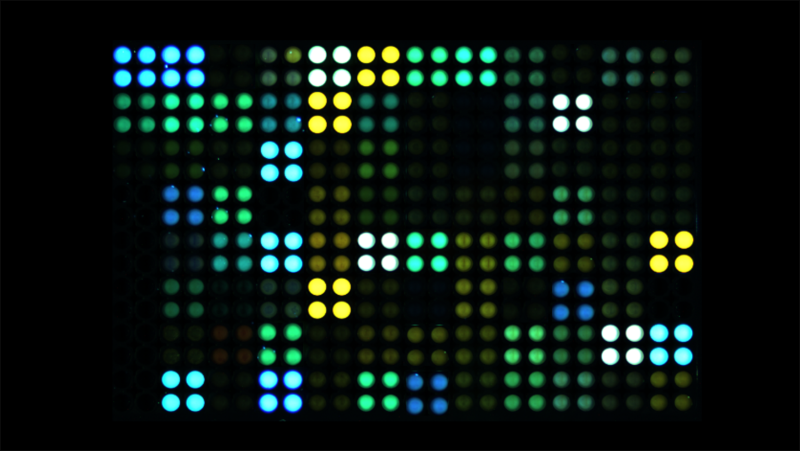

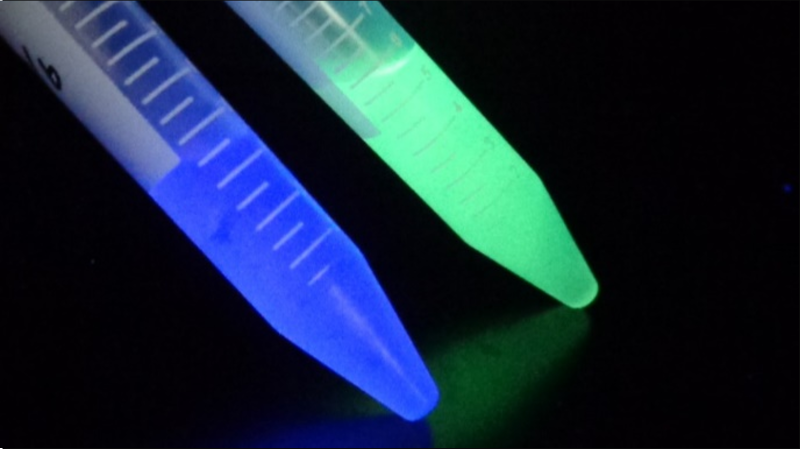

Development of a highly versatile molecule sensor requires various fluorescent probes that can accurately identify different interactions. Konica Minolta has advanced technologies and expertise for selecting optimal molecular probes for measurement targets from more than 300 types of fluorescent molecule libraries. Countless fluorescent probes can be created efficiently for various uses. These probes are designed by taking into account factors including luminescent colors, luminescence mechanisms, and types of interactions, and are optimally selected depending on the measurement target.

These fluorescent probes created by Konica Minolta change their structures through reactions with electric charges from measurement targets and structural affinity. As a result, the luminescent intensity and luminescent colors change almost continuously and are recorded as RGB data. Thus, information in hundreds of dimensions is accumulated and used for AI analysis.

Konica Minolta has been developing the FLAIRS liquid evaluation solution, which can handle the entire process from data measurement to AI analysis. For details of the technology, click/tap the link of the relevant technology.