Technology

Industry

- Contactless, remote anomaly detection and risk prediction

- Providing valuable components to accommodate industry evolution and diversification

- Contribution to process innovation and high-quality manufacturing in the supply chain via visualization

Contactless, remote anomaly detection and risk prediction

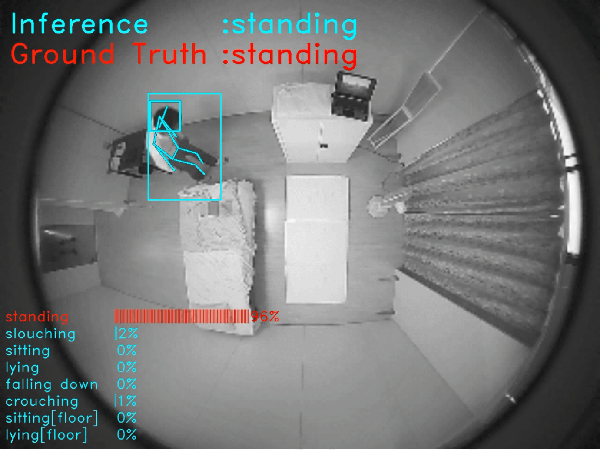

IoT and DX of production sites: image recognition technology that visualizes unsafe behavior

Offering a safety behavior support system that visualizes the behavior of on-site workers

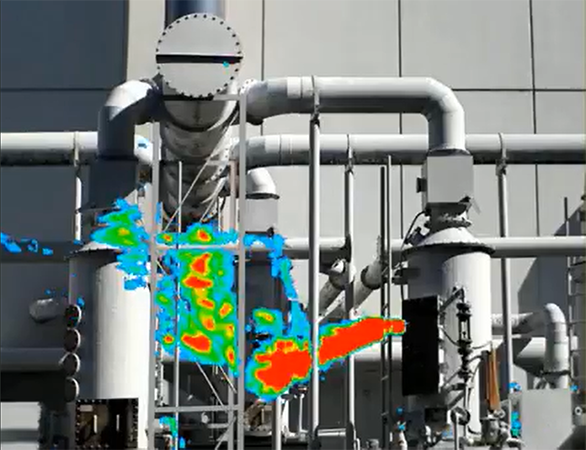

Infrared image analysis technology

Visualizing invisible gases to ensure security and safety and reduce greenhouse gas emissions

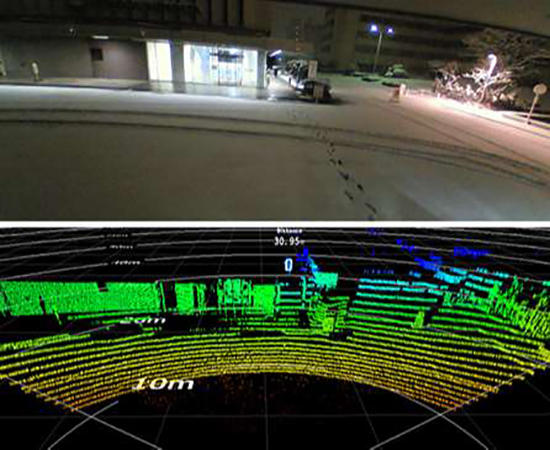

3D image analysis technology

Improving the workflow and increasing the efficiency of security services by 3D scanning and moving object analysis technology

Providing valuable components to accommodate industry evolution and diversification

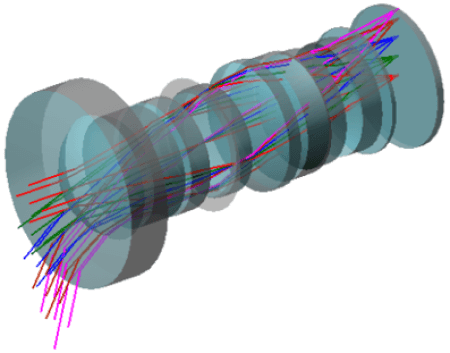

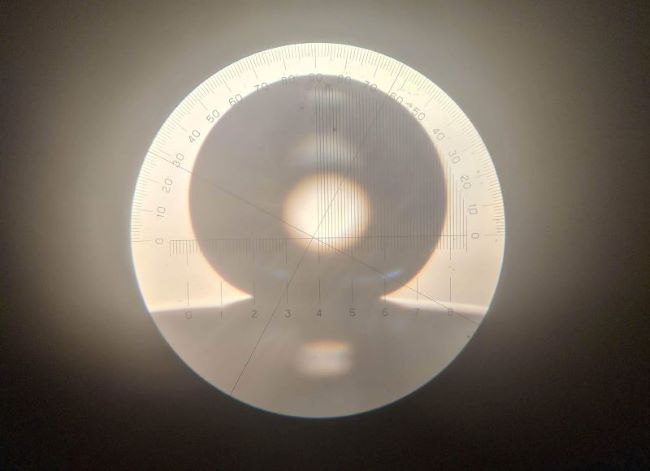

Optical system design and evaluation technology enabling both outstanding optical performance and mass production

Minimizing defects in mass production by using simulation technology

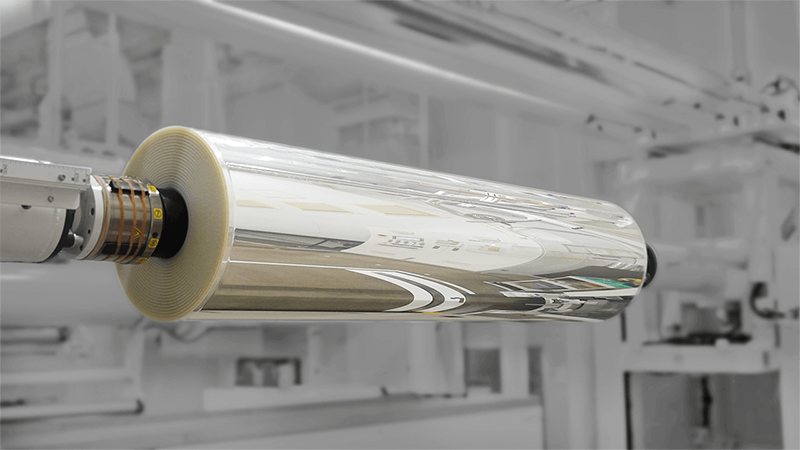

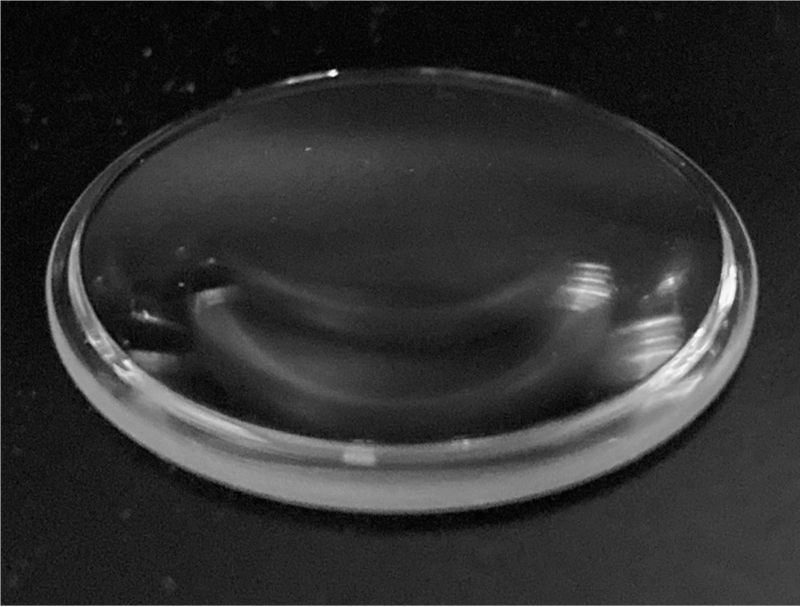

Glass-resin hybrid lens molding technology

Achieving optical systems with reduced footprint and weight by using lenses featuring the advantages of two materials

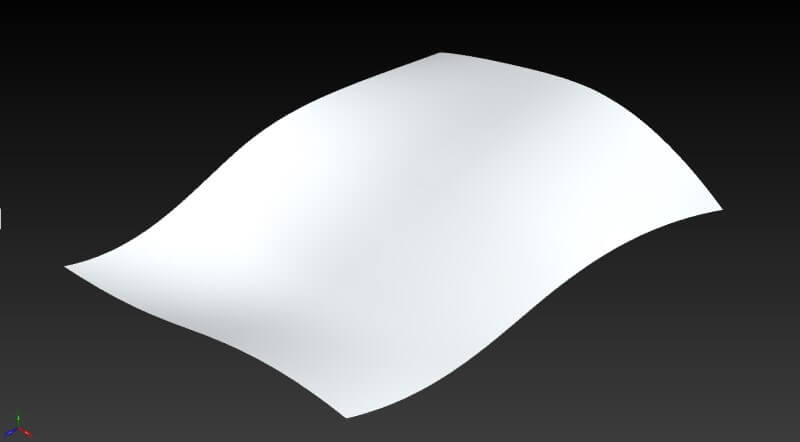

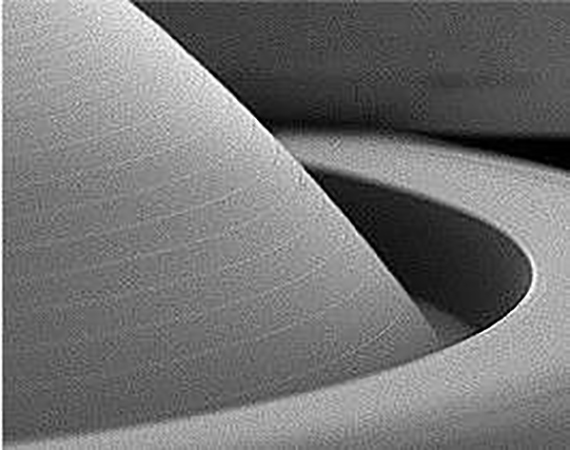

Free-form surface processing technology for optical elements

Achieving space-saving, high-resolution optical elements of the next generation

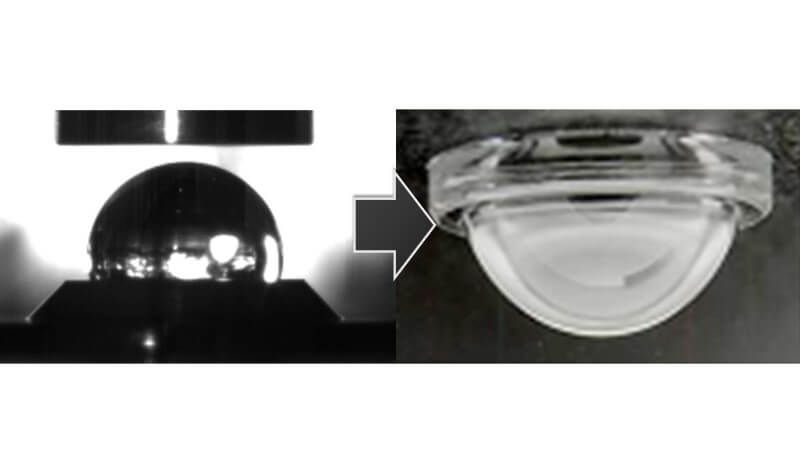

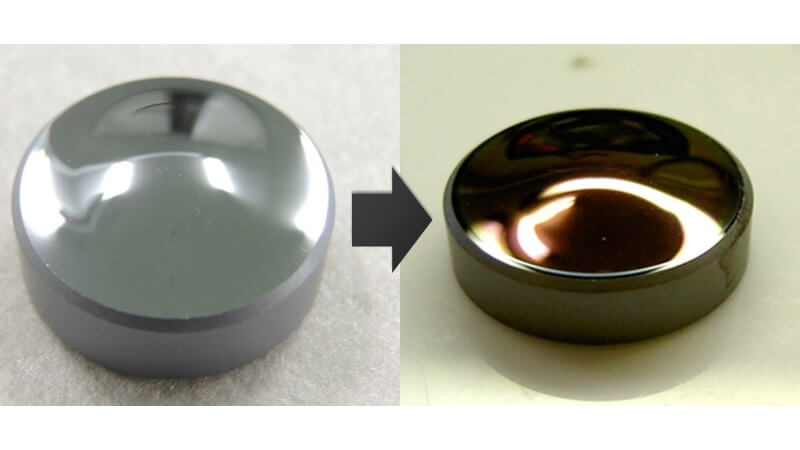

Glass molding technology to produce lenses having complex shapes by the unique droplet method

Optical systems for new applications achieved by flexibility of shape

Thin layer coating technology for optical parts

Imparting desired characteristics by forming a functional thin layer

Super-hydrophobic coating technology

Providing highly durable hydrophobic properties by forming a rough nanostructure by etching

High-durability hydrophilic coating technology for lens surfaces

Ensuring a clear view for cameras free from water droplets even in rainy weather

Mold fine shape processing and transfer technology

Flexibly imparting high functionality to resins and glass with high reproducibility by using transfer technology

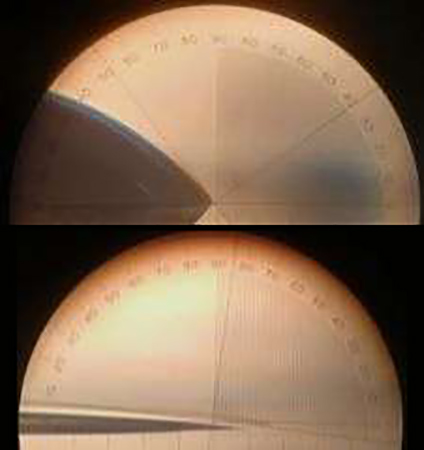

High-accuracy far-infrared glass lens technology

Achieving high flexibility in designing arsenic- and selenium-free chalcogenide glass

Inkjet printhead technology for industrial use

Realizing printheads suitable for various manufacturing processes based on ink compatibility and precision machining technology

Technology for enhancing the durability of IJ printheads

Compatibility with a wide variety of inks ensured by our original material design technology

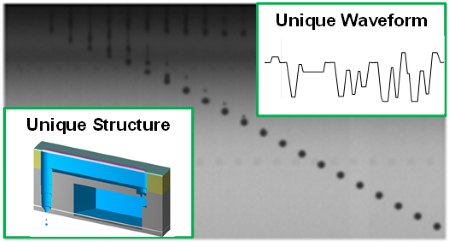

High-gap ink ejection technology

Achieving high-quality character printing even when the gap between the IJ printhead and the media is large

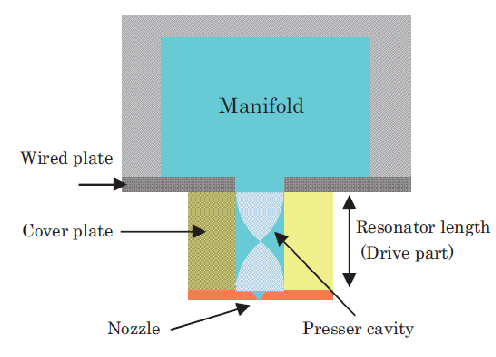

Multi-row thin type actuator technology

IJ printheads equipped with a unique harmonica structure achieving high-definition printing on various media

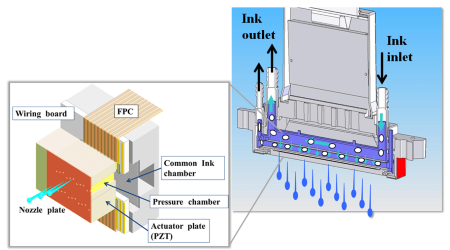

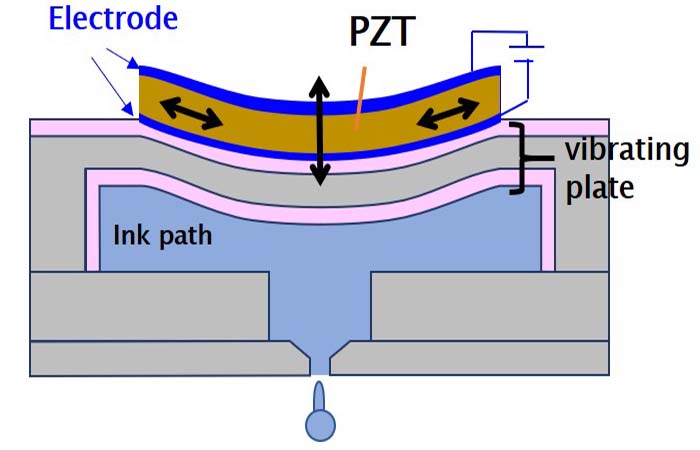

Ink-non-contact PZT actuator technology

Achieving high compatibility with functional inks used in industrial fields by using a unique printhead structure

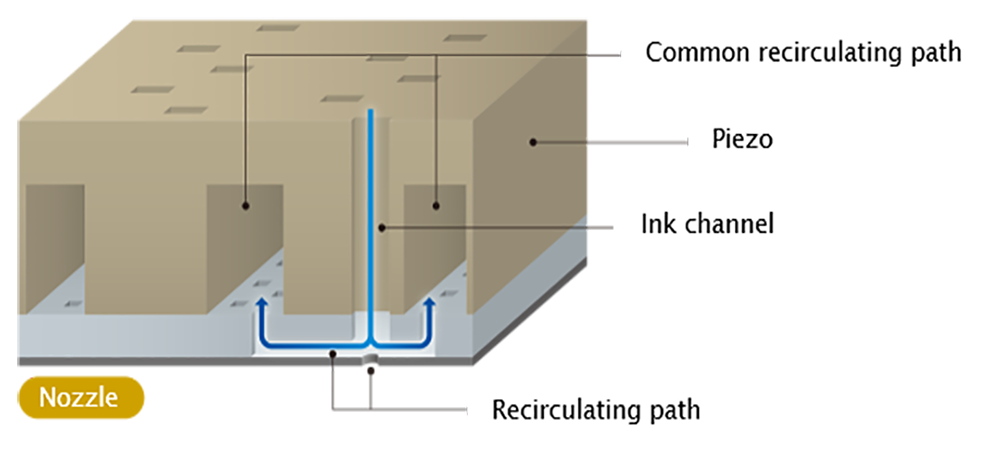

Nozzle recirculation technology

Contributing to higher productivity and quality in industrial fields by improving the recirculation and jetting performance

Silicon nozzle technology

Realizing high accuracy of dot placement and a wide media gap by nozzle hole forming technology using MEMS

Contribution to process innovation and high-quality manufacturing in the supply chain via visualization

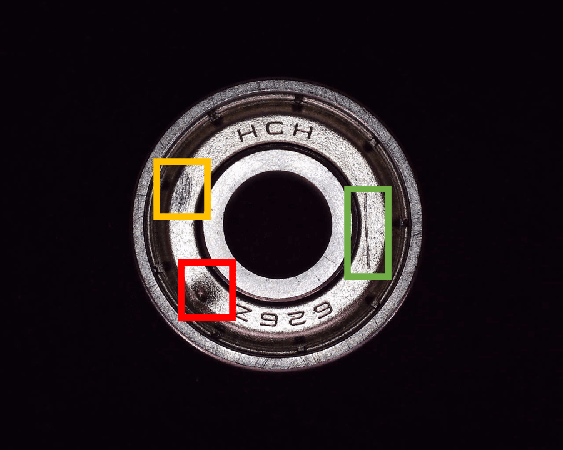

Visual inspection technology

Highly accurate defect judgment technology that can be easily customized depending on the application

Automatic inspection technology for automotive production lines

Automating the inline paint quality inspection of car bodies

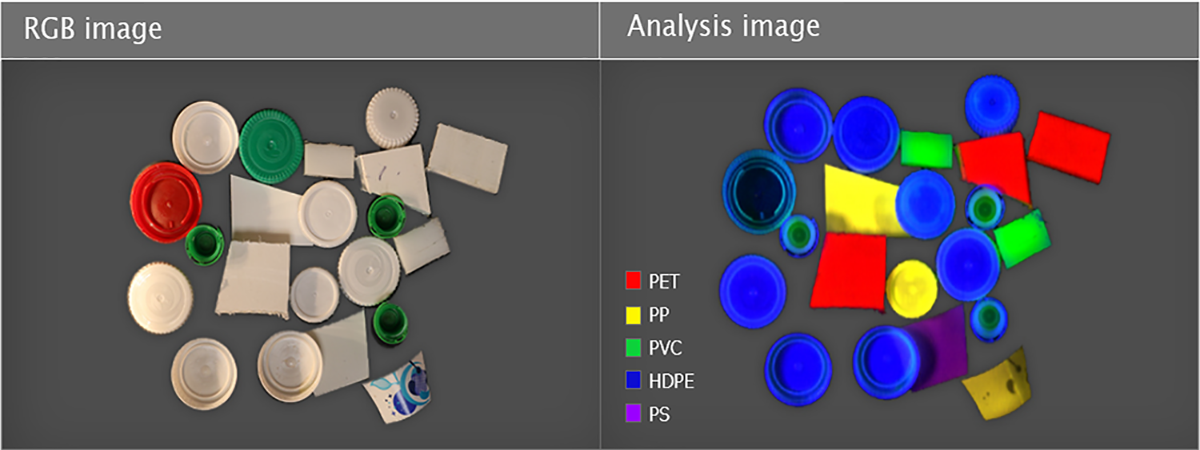

Hyperspectral imaging technology (HSI)

Realizing highly accurate determination and inspection by processing spectral information of visible light or higher frequencies